Full Stream Ahead

KODAK PROSPER Print Bar with Stream Inkjet Technology features unmatched speed and precision.

Kodak takes the speed and efficiency advantages of continuous inkjet to the maximum with KODAK Stream Inkjet Technology

With nearly six decades of high-speed inkjet expertise, Kodak stands at the forefront of the transformation from traditional to digital printing. By leveraging continuous inkjet (CIJ) technology, Kodak is redefining what’s possible in commercial, publishing, and packaging printing, all while meeting the demands of modern, efficient production.

Unlike many other manufacturers, who rely on drop-on-demand (DOD) inkjet technology, Kodak utilizes CIJ with eco-friendly, water-based inks in its digital presses and digital imprinting solutions. While DOD systems create drops only when required for printing via a piezo vibration inside the nozzle chamber or tiny thermal explosions, CIJ printheads produce a nonstop curtain of ink drops. This continuous drop generation enables the very high printing speeds of CIJ and provides a variety of additional advantages. KODAK Stream Inkjet Technology, Kodak's fastest CIJ technology, utilizes air deflection to manage non-printing drops. The printing drops go directly onto the substrate, and the non-printing drops are deflected into a recirculation gutter for reuse.

CIJ delivers measurable advantages

One significant advantage of KODAK Stream Inkjet Technology is its uniform quality, achieved with exceptional drop uniformity and drop placement accuracy. CIJ produces high-resolution images with enhanced clarity, minimizing jagged edges on text and lines due to its precise, rounded ink drop technology. Kodak’s nanotechnology pigments and low-humectant inks deliver accurate control of pigment density through print production, resulting in more consistency and higher quality than DOD. The velocity of a Stream ink drop is 20 meters per second, significantly faster than the average 8 meters per second of competitive DOD systems. This speed increases drop placement accuracy for offset-class quality. The combination of velocity and quality directly correlates to turning jobs quickly and reliably with more value and profit.

Another advantage of Stream is its high velocity, allowing the printhead’s nozzle plate to be positioned up to eight times further away from the substrate, thereby reducing the risk of printing errors, such as printhead strikes, and the incurring costs. In DOD, there is a higher risk of damage to the print and printheads. As the print substrate moves rapidly closer to the printheads, even slight variations in its position or tension can lead to potential collisions.

One of the standout benefits of Kodak’s continuous drop generation is its ability to keep the printing system running at peak performance with minimal interruptions. By continuously generating and recirculating ink drops, the technology prevents ink from drying or building up in the jetting modules, which minimizes clogging and maintains clear, operational printheads. This reliability allows for longer press runs, higher throughput, more consistent output, and reduced maintenance costs.

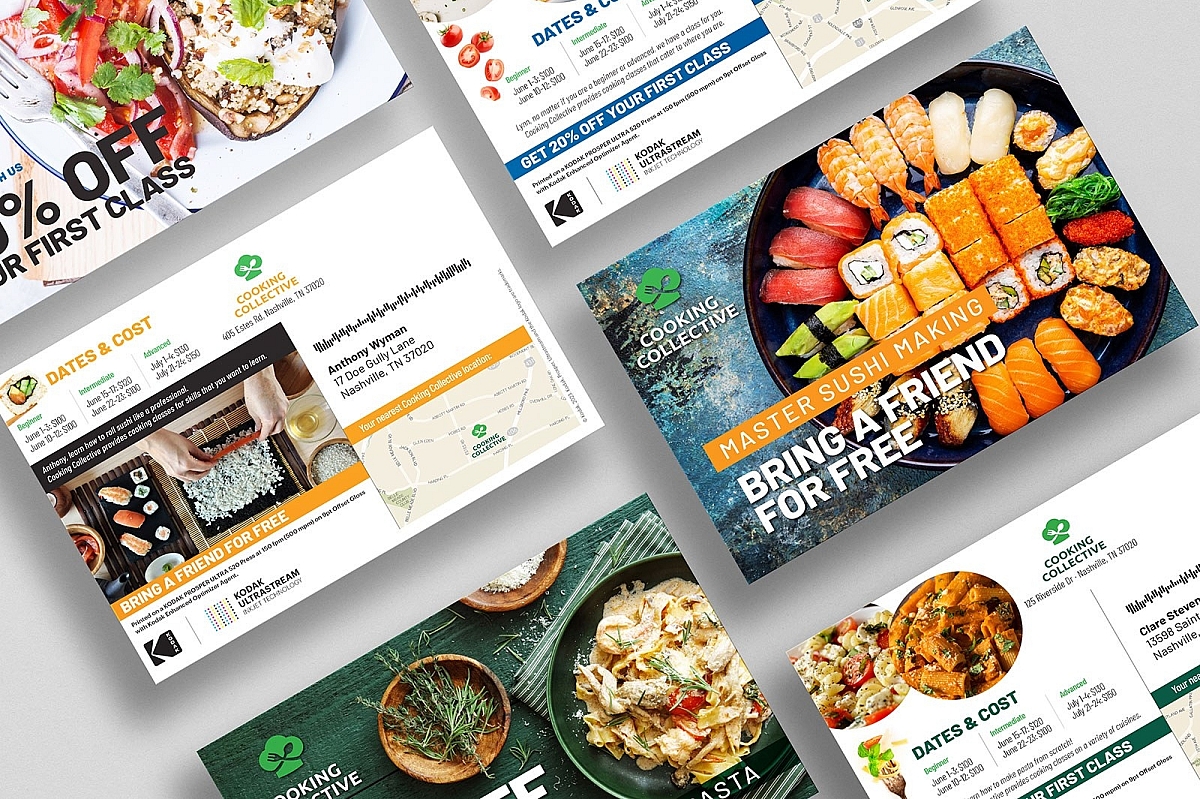

KODAK Stream Inkjet Technology’s uncompromising speed is at the heart of the KODAK PROSPER 7000 Turbo Press, the world's fastest digital press with speeds of up to 410 mpm (1,345 fpm), and the proven PROSPER 6000 Press. The versatile KODAK PROSPER Print Bar, KODAK PROSPER Plus, and PROSPER S-Series Imprinting Systems, which integrate with analog printing presses, finishing equipment and other production lines, also employ Stream Inkjet Technology, achieving print speeds of up to 900 mpm (3,000 fpm), depending on the model.

Kodak Stream Technology delivers perfectly round, vibrant drops, ensuring exceptional print quality for a variety of applications.

Stream, EKTACOLOR Inks and OPTIMAX Primers make a perfect team

The outstanding capabilities of Stream Inkjet Technology are supported by the unique properties of water-based KODAK EKTACOLOR Inks. The inks are specially formulated to produce brighter, clearer and more vibrant print at speeds that surpass other inkjet systems on the market. EKTACOLOR Inks are manufactured using Kodak's proprietary pigment micro-milling technology, which generates extremely fine nanoparticle pigments, typically less than 50 nanometers in size (2,000 times smaller than the diameter of a human hair) with a very narrow size distribution. The finer pigments make the ink easier to jet, minimize light scatter, and deliver ultra-thin dried ink layers as well as a superior color gamut. Stream Inkjet Technology systems print vivid images with vibrant colors and reliably render the CMYK offset gamut. Another differentiating feature of EKTACOLOR Inks is a lower level of humectants compared to inks from competitors. This results in faster drying, even when printing with high ink coverage on difficult substrates.

The inks are complemented by water-based KODAK OPTIMAX Primers, ensuring compatibility with a wide range of substrates. OPTIMAX Primers improve ink receptivity, ink adhesion, rub resistance, and quality of the printed image on most types of paper, cardboard, plastic and film. Together, EKTACOLOR Inks and the suitable OPTIMAX Primers empower Stream Inkjet Technology to reliably produce an enormous range of applications across diverse substrates. Beyond commercial, direct mail and publishing applications, EKTACOLOR Inks are also suitable for cardboard, corrugated board and film packaging and even for personal care applications.

Brilliant colors burst to life on the KODAK PROSPER 7000 Turbo Press as KODAK EKTACOLOR Inks and OPTIMAX Primers combine for stunning, vivid images.

Inkjet’s workhorse

Stream Inkjet Technology, featured in KODAK PROSPER Presses and PROSPER Imprinting Systems, is a true high-power workhorse that combines design simplicity, printhead reliability and high productivity in a platform that offers low operating costs, high print quality and stunning speed levels. This Kodak technology efficiently supports printers in meeting individual customer needs more swiftly and becoming more productive and profitable in the digital printing business.