Slam dunk as Modern Litho delivers NCAA tournament programs

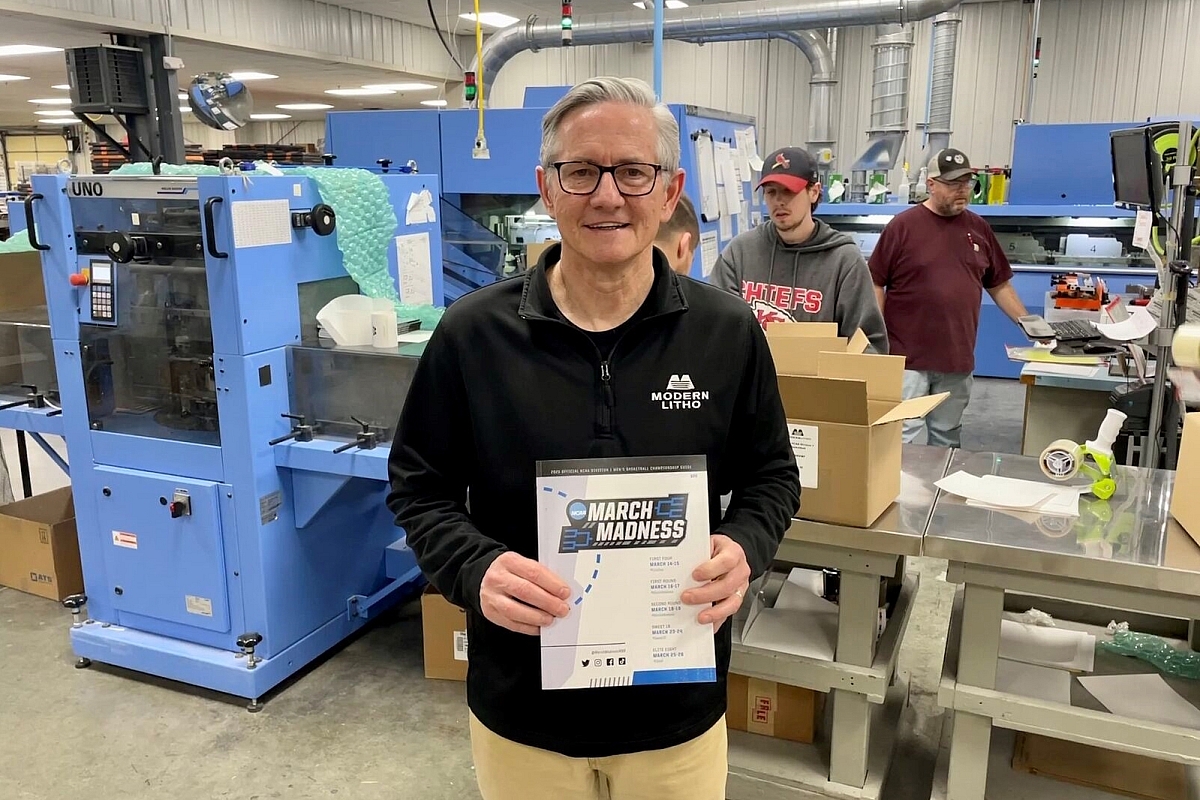

Jim Tomblinson, COO for Modern Litho holding a freshly minted NCAA tournament program that they prepared, produced and shipped in less than 24 hours.

The NCAA basketball tournament is one of the most popular sporting events of the Spring. It builds to a crescendo as single-elimination games feed the brackets until the final four teams meet to compete for the final two slots to determine the men's and women's champions. In each host city, printers work against tight deadlines to produce the programs for the fans. Production can only begin once the NCAA sets the brackets, so how do those fabulous programs get printed?

Modern Litho knows! Working with their customer LEARFIELD, the Modern Litho team leveraged their experience in quick turnaround work to prepare, print, fold, bind, and ship from the dock in less than 24 hours.

It started with a call from the team at LEARFIELD. Their previous printer declined the project due to declining run lengths, but the volume requirements perfectly fit into the Modern Litho wheelhouse. With a 30-year history working with Modern Litho, they started discussions several months ahead to identify the requirements from file delivery to the final product. Jim Tomblinson, Modern Litho Chief Operating Officer, says, “I have confidence in our Kodak software, Heidelberg equipment, and the experience of our team, so it took me about 30 seconds to decide we could do this for them.”

The job had tight deadlines since LEARFIELD had to wait until Selection Sunday®, March 12, to finalize files. Tomblinson says files began arriving in their KODAK PRINERGY INSITE Portal at 6:15 p.m. and kept on coming until 7:45 p.m. for the men's final. The approval process was precisely 15 minutes, completed by 8 p.m. – all made possible by PRINERGY and INSITE managing the inbound files and PRINERGY’s Rules Based Automation (RBA) efficiently moving files through the process to the plates.

A 24-Hour Quick Turn

Zero failures is the goal for all work produced at Modern Litho. Tomblinson says that the KODAK PRINERGY Business Solutions provided the tools and the operational visibility needed to meet their deadlines without a single mishap and maintain their record. To meet the tight deadlines, perfectly executed preparation was the key. Modern Litho's Josh Crawford, PRINERGY Administrator, and his team built a plan that began before the files arrived in the INSITE portal.

While Crawford and his team spent the weekend with their families, INSITE, PRINERGY, and the RBA processes waited for the files and put them into the workflow as they arrived. RBA routed the files through to each task, first to ripping and then to KODAK COLORFLOW Software for color management. The Modern Litho team says that the beauty of their PRINERGY system is that once a workflow is defined it will work 100% of the time. Still, Crawford admitted to peeking in on the high-profile job to ensure everything was moving through the workflow.

Once the proofs were ready, they were posted back to the INSITE portal for speedy review by the Learfield team, who completed most approvals within 15 minutes of receiving them. From proof approval, the automation moved to page imposition for the proper layout downstream. The next stop was the KODAK SONORA Process Free Plates* for the great detail on every image. Plates then moved to the press for print execution.

Tomblinson shared that one of his responsibilities was to execute the timely printing of signatures on their three Heidelberg XL long perfectors for efficient folding and binding. The solution was to print the men's and women's programs simultaneously on the night shift, making it a long night for Tomblinson. He press-checked each form before letting them move to the next stage, where the Heidelberg Stahlfolder KH and TH machines took over.

From start to finish, Modern Litho relies on its team's commitment to the business every day. Their process includes pre-meetings to plan each step, from the first conversation with the customer to job delivery, identifying potential bottlenecks and friction points ahead of time so the job can run efficiently. That is essential when a demanding job like this comes into the shop. Tomblinson says that delivery is key, "But we make sure our quality comes with it. We are always looking for these types of opportunities. With Kodak, Heidelberg and our team we feel very confident!"

*SONORA XTRA-3 Plates are not available in Germany.