Phosphate Buffered Saline (PBS)

Consistent performance. Smarter choice.

Run assays, prep samples, and scale programs without introducing doubt or disruption.

Whether you’re advancing discovery or preparing for tech transfer, Kodak PBS delivers the flexibility and dependability to keep science moving forward.

Water for Injection (WFI)

High purity. GMP confidence.

Prepare formulations, support aseptic processing, and power sterile workflows with WFI you can trust at every stage.

For biological buffers, process solutions, and bioprocessing solvents, Kodak WFI offers the quality, documentation, and dependability to keep your programs on track.

Custom Pilot & Mid-Batch Solutions

Tailored to your process. Scaled to your stage.

Move from discovery to development with buffer volumes and formulations designed for your exact needs. Kodak delivers custom pilot- and mid-batch GMP solutions that help you optimize processes, qualify workflows, and prepare for tech transfer, without locking you into rigid catalog specs or bulk volumes too early.

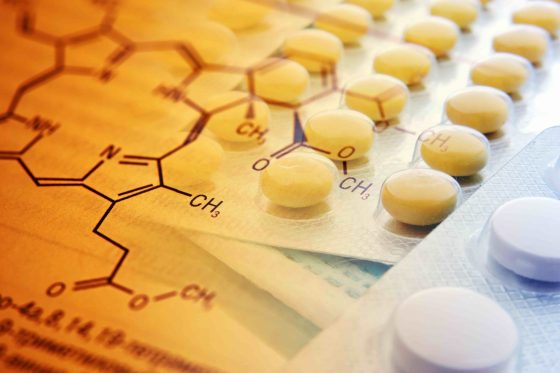

Key Starting Materials (KSMs) for Active Pharmaceutical Ingredients (APIs)

Precision made. Partnership driven.

With decades of experience in custom synthesis and high-quality production serving diverse markets, Kodak collaborates with pharmaceutical Contract Manufacturing Organizations (CMOs) manufacturing non-regulated Key Starting Materials (KSMs) for Active Pharmaceutical Ingredients (APIs).

A Legacy of Excellence

With over 130 years of expertise in advanced materials and chemicals, Kodak brings unparalleled reliability to the pharmaceutical sector. As a trusted partner in delivering KSMs to the pharmaceutical industry, we are now expanding to regulated products enabling pharmaceutical development.

FDA-Regulated Facility

cGMP Quality Systems

Reliable Supply Chain

Made in USA

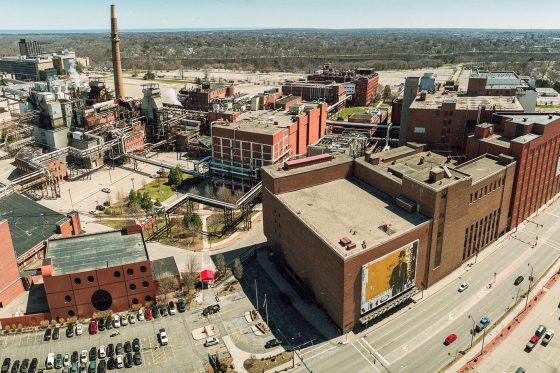

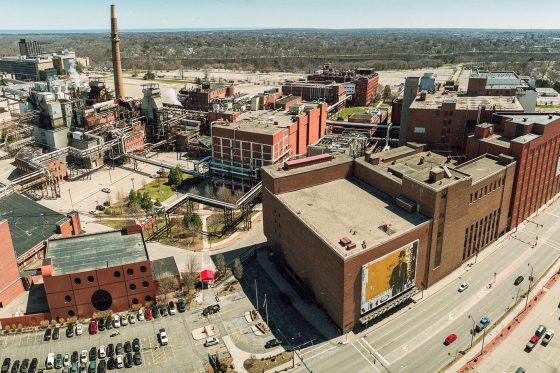

Our Facility: U.S.-Based. cGMP. Non-negotiable Water Quality.

Your solutions are manufactured in the Eastman Business Park, located in Rochester, N.Y. Our cGMP facility is built to deliver confidence in every lot. Designed for life science workflows, it combines advanced infrastructure with rigorous quality systems to meet the highest standards.

- 30,000 sq ft FDA-compliant cGMP facility

- Modern multi-step water purification system

- Full traceability and documentation with each lot

- Dependable access to a clean water supply

- Designed for optimized energy use, reducing greenhouse gas emissions