KODAK PROSPER ULTRA 520 Press

Increase profits by transitioning higher-cost offset jobs to the KODAK PROSPER ULTRA 520 Press with no compromises on quality or speed. For high-value, high-ink coverage applications like magazines and catalogs get offset image quality and productivity with the flexibility and economy of inkjet.

CONTINUOUS PRODUCTIVITY. CONTINUOUS PROFITABILITY. CONTINUOUS INKJET.

2-3xfaster

2-3xfasterQuicker than the competition, with a consistent 152 mpm (500 fpm) print speed on anything from uncoated to glossy papers

- 200lpi

Offset-comparable print quality this press achieves, thanks to ULTRASTREAM Inkjet Technology

- 1.4xlarger

Meet the demands of most discerning customers with a larger color gamut than GRACoL and Fogra standards

- 101percent

More pages moved from offset to inkjet than other DOD devices

Continuous Inkjet Technology

- Print 200 lpi offset quality with Kodak’s innovative ULTRASTREAM Inkjet Technology.

- Sharper, higher-resolution print than standard drop-on-demand technology thanks to perfectly round, precisely targeted ink drops.

- Ultimate color fidelity, line straightness, highlights, details, and consistency over long runs.

Higher profit margins

Investing in the PROSPER ULTRA 520 Press pays off:

- Higher run-length cross-over with offset

- KODACHROME Ink optimization with KODAK COLORFLOW Software

- Increase uptime without printhead clogs

- Reduce labor and waste

Reduce Risk and Stay Competitive

With stretched supply chains, rising resource costs, tight margins, and ongoing labor challenges, stay ahead of the competition with the PROSPER ULTRA 520 Press.

- Offset image quality

- High productivity

- Application flexibility

- Low cost per image

Compact and Capable

More compact than most of the competition with an open architecture that integrates easily with pre- and post-press equipment. The KODAK 900 Print Manager makes press control and job management a breeze. Integrate KODAK PRINERGY Workflow or third-party software for automation and additional efficiencies.

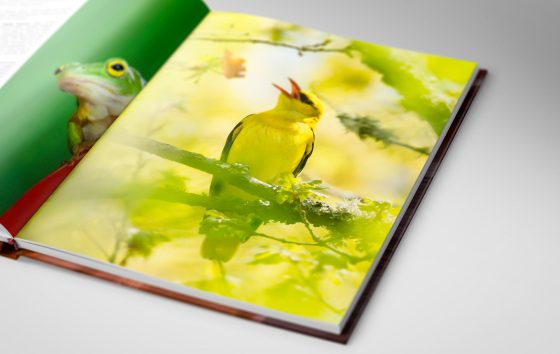

Print your true colors

KODACHROME Inks deliver brighter, sharper, purer colors compared to offset. Micro-milled, nanoparticulate pigments result in exceptional color purity and astounding optical density. Paired with KODAK OPTIMAX Primers allows printing on practically any substrate.

Read more about Kodak Inkjet Inks

Compete in High-Value Markets

The PROSPER ULTRA 520 Press prints on a range of substrates—coated, uncoated, and even glossy— for countless applications. Unlock the power of inkjet’s cost-effectiveness and variable data flexibility to offer even more to your most demanding clients in publishing, marketing, and beyond.