Facts that Win: Setting the record straight on process-free plates

Cutting Through the Noise

In today's print industry, misinformation travels fast. But at Kodak, we believe that facts, and performance, speak louder than words. With over a century of innovation and more than 20 years leading the process-free plate revolution, it's time to separate fact from fiction and show why KODAK SONORA Process Free Plates set the standard for excellence, sustainability, and reliability.

Fiction vs. Fact: Debunking the Myths

Fiction #1: All Process Free Plates Are the Same

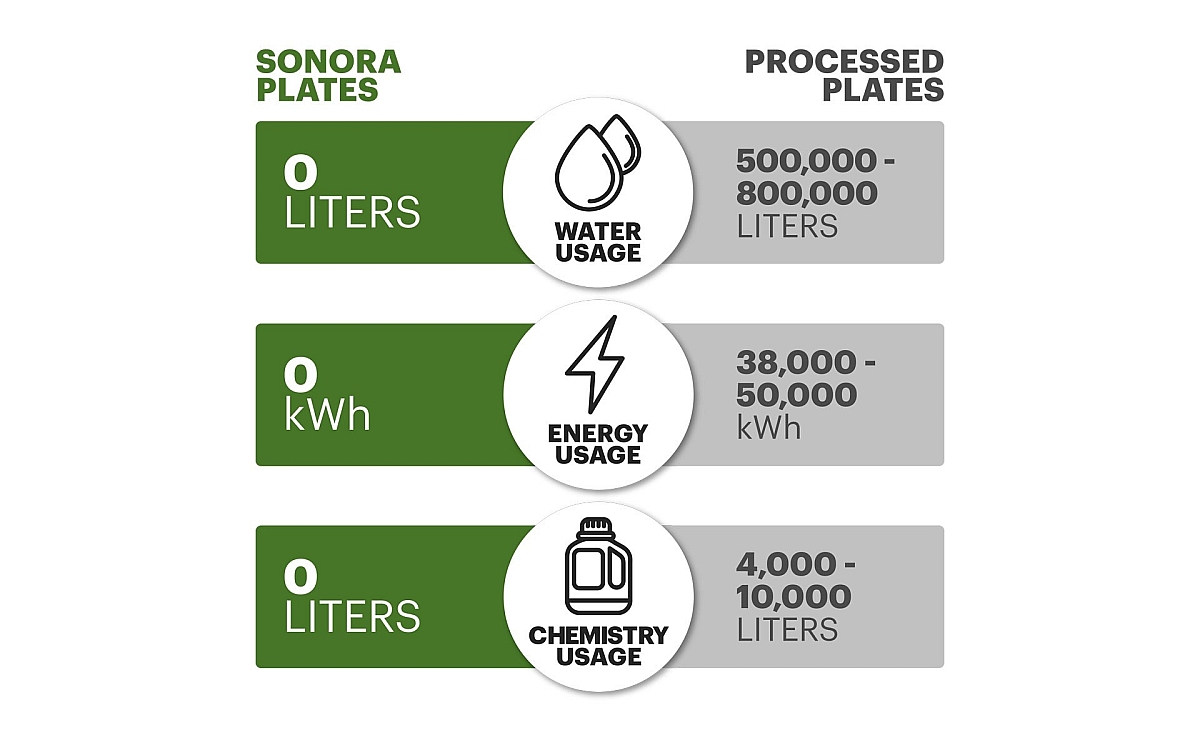

Fact: Not all process free plates are created equal. KODAK SONORA Process Free Plates eliminate the need for processors, chemistry, and water, offering a truly process-free solution. In contrast, many so-called "chem-free" or "process-less" plates still require post-imaging cleanup and chemical waste disposal. With SONORA, you get a cleaner, simpler, and more sustainable process.

Fiction #2: Competitors Lead in Sustainability

Fact: At Kodak, we don't just make plates, we make progress. Our commitment to sustainability is unmatched, and our plates help printers reduce waste, energy use, and environmental impact.

Kodak has already helped the print industry save significant resources by enabling thousands of printers worldwide to adopt SONORA Process Free Plates. On average, these efforts have resulted in annual savings of:

- 57 million liters of plate developer

- 575 million kWh of electricity

- 8.5 billion liters of water

And the potential for even greater impact remains—if more printers make the switch to SONORA, these savings will continue to grow, driving further progress for sustainability across the industry.

Fiction #3: All Plates Perform the Same

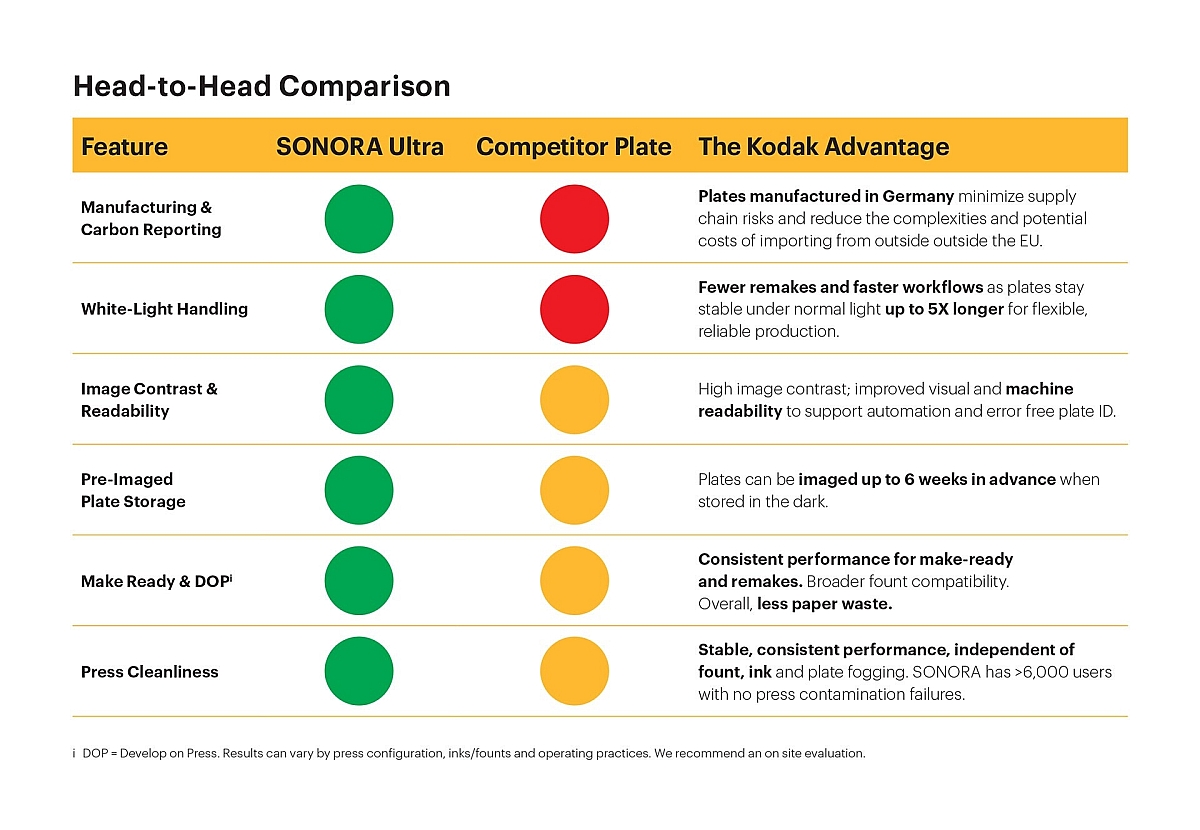

Fact: KODAK SONORA Process Free Plates deliver superior performance proven across over 6,000 customer installations worldwide. SONORA plates stay stable under normal light for significantly longer than competing options, reducing remakes and enabling faster, more reliable workflows. Their high image contrast and exceptional machine readability support accurate automation and errorfree plate identification, while consistent makeready performance and broad fount compatibility help printers minimize waste and maintain production efficiency. SONORA plates are also known for their stable, consistent performance with no press contamination failures. Together, these advantages show that SONORA delivers measurable performance benefits competitors cannot match.

Fiction #4: Process Free Plates Are All Manufactured the Same Way

Fact: KODAK SONORA Ultra Process Free Plates are solely manufactured in Germany using aluminum sourced from Europe. This ensures full traceability, a reduced carbon footprint, and simplified sustainability reporting. Unlike imports from outside Europe, which often rely on carbon-intensive aluminum and may face growing regulatory risks like CBAM, Kodak's localized production supports both quality and environmental responsibility.

Performance That Speaks Louder Than Words

Kodak's legacy of innovation continues to drive us forward. Our commitment to precision and reliability is reflected in the solutions we provide, and our Savings Estimator tool gives printers a personalized look at how much they could save by switching to SONORA Process Free Plates. Real savings, based on real numbers.

Ignore the Noise. Print with Confidence.

In a crowded market, clarity matters. Kodak remains a trusted partner for those who demand excellence. We're here to deliver what matters most to our customers every single day: trusted quality, reliability, and innovation. Ready to see the difference for yourself? Let's connect and keep the conversation going.