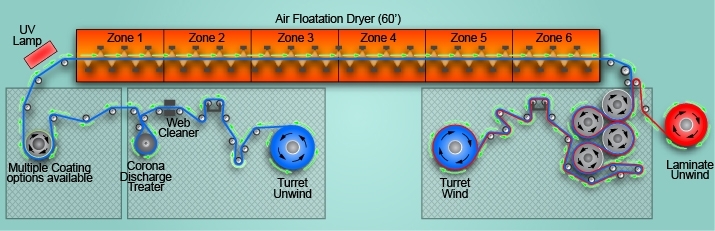

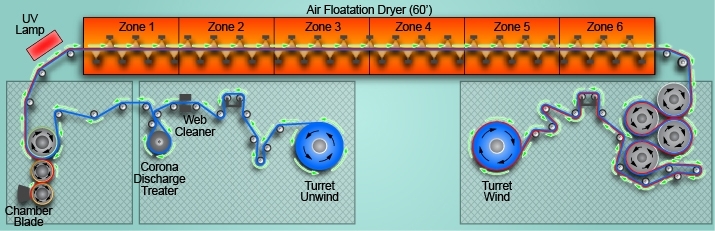

- Aqueous and solvent solutions up to 10,000 cps

- Solution volumes as low as 3 liters

- Gear, diaphragm, Moyno, Waukesha pump options

- Pressure vessel delivery option

- Plastic, paper, and metal webs at thickness of 5 microns and up

- Web widths up to 17"

- Web speeds of 5 to 1000 fpm

- In-line CDT prior to coating

- 60’ Drying/curing oven at temperatures up to 450° F

- Nitrogen purge, 600 W/in UV lamp with D/H/H+ bulb options

- Additional configuration options include:

- Wet and dry lamination

- In-line roller nip at exit of drying oven

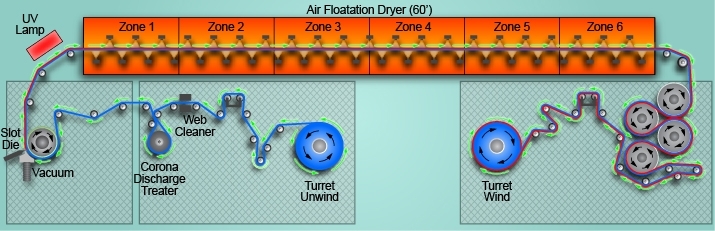

- Aqueous solutions up to 10,000 cps

- Solution volumes as low as 3 liters

- Gear, diaphragm, Moyno, Waukesha pump options

- Pressure vessel delivery option

- Plastic, paper, and metal webs at thickness of 5 microns and up

- Web widths up to 17"

- Web speeds of 5 to 1000 fpm

- In-line CDT prior to coating

- Four 35 kW NIR heaters from Adphos prior to oven

- 60’ Drying/curing oven at temperatures up to 450° F

- Nitrogen purge, 600 W/in UV lamp with D/H/H+ bulb options

- Additional configuration options include:

- Dry lamination

- In-line roller nip at exit of drying oven

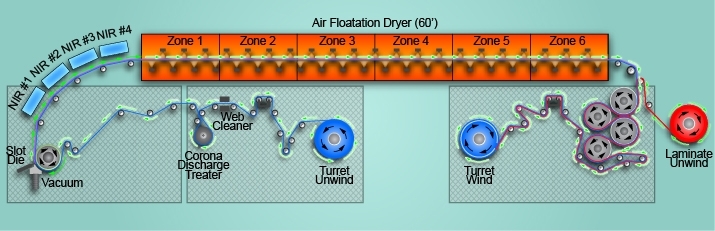

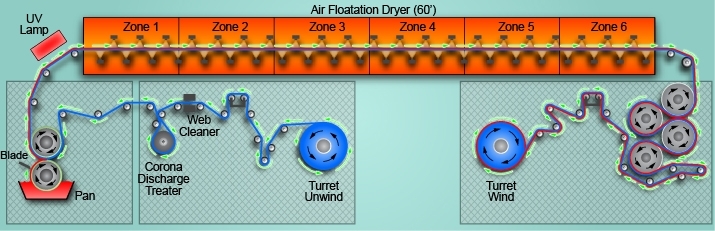

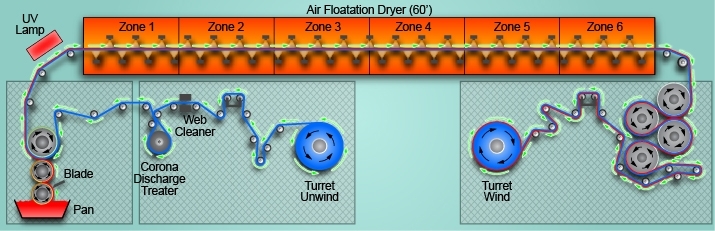

- Aqueous and solvent solutions

- Pan volumes of 1, 2, and 12 liters

- Multiple cylinders available with wet thickness from 1 to 20 microns

- Nitrogen-inert shroud option available

- Electrostatic assist coating option

- Plastic, paper, and metal webs at thickness of 5 microns and up

- Web widths up to 17"

- Web speeds of 50 to 5000 fpm

- In-line CDT prior to coating

- 60’ Drying/curing oven at temperatures up to 450° F

- Nitrogen purge, 600 W/in UV lamp with D/H/H+ bulb options

- Additional configuration options include:

- Wet and dry lamination

- In-line roller nip at exit of drying oven

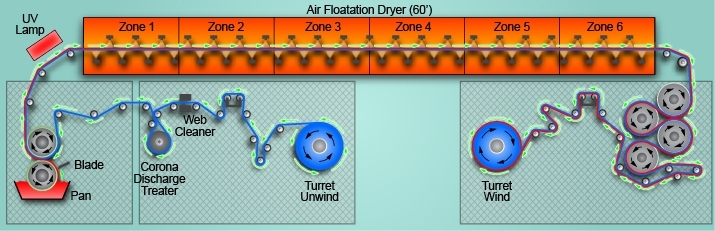

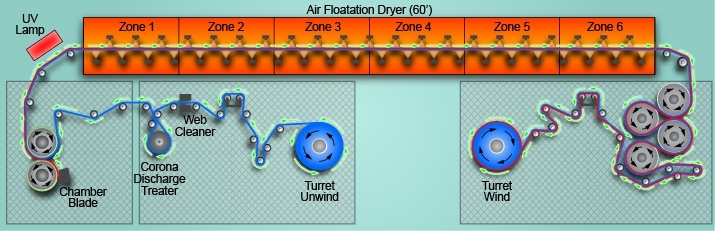

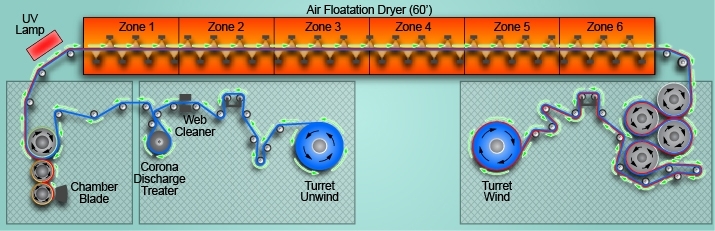

- Aqueous and solvent solutions

- Chamber blade system volume – 6 and 12 liter options

- Multiple cylinders available with wet thickness from 1 to 20 microns

- Electrostatic assist coating option

- Plastic, paper, and metal webs at thickness of 5 microns and up

- Web widths up to 17"

- Web speeds of 50 to 5000 fpm

- In-line CDT prior to coating

- 60’ Drying/curing oven at temperatures up to 450° F

- Nitrogen purge, 600 W/in UV lamp with D/H/H+ bulb options

- Additional configuration options include:

- Wet and dry lamination

- In-line roller nip at exit of drying oven

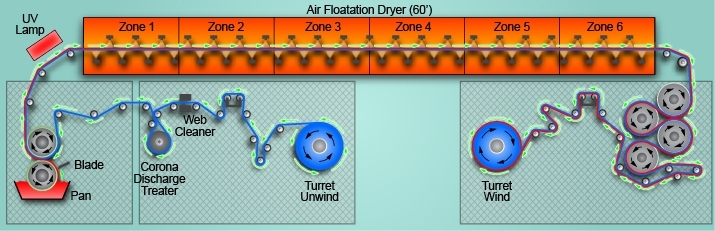

- Aqueous and solvent solutions

- Pan volumes of 1, 2, and 12 liters

- Multiple cylinders available with wet thickness from 1 to 20 microns

- Nitrogen-inert shroud option available

- Electrostatic assist coating option

- Plastic, paper, and metal webs at thickness of 5 microns and up

- Web widths up to 17"

- Web speeds of 50 to 5000 fpm

- In-line CDT prior to coating

- 60’ Drying/curing oven at temperatures up to 450° F

- Nitrogen purge, 600 W/in UV lamp with D/H/H+ bulb options

- Additional configuration options include:

- Wet and dry lamination

- In-line roller nip at exit of drying oven

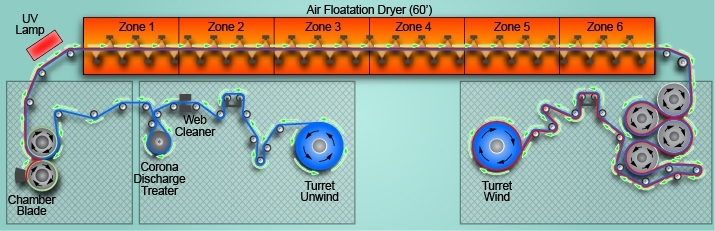

- Aqueous and solvent solutions

- Chamber blade system volume – 6 and 12 liter options

- Multiple cylinders available with wet thickness from 1 to 20 microns

- Electrostatic assist coating option

- Plastic, paper, and metal webs at thickness of 5 microns and up

- Web widths up to 17"

- Web speeds of 50 to 5000 fpm

- In-line CDT prior to coating

- 60’ Drying/curing oven at temperatures up to 450° F

- Nitrogen purge, 600 W/in UV lamp with D/H/H+ bulb options

- Additional configuration options include:

- Wet and dry lamination

- In-line roller nip at exit of drying oven

- Aqueous and solvent solutions

- Pan volumes of 1, 2, and 12 liters

- Multiple cylinders available with wet thickness from 1 to 20 microns

- Plastic, paper, and metal webs at thickness of 5 microns and up

- Web widths up to 17"

- Web speeds of 50 to 5000 fpm

- In-line CDT prior to coating

- 60’ Drying/curing oven at temperatures up to 450° F

- Nitrogen purge, 600 W/in UV lamp with D/H/H+ bulb options

- Additional configuration options include:

- Wet and dry lamination

- In-line roller nip at exit of drying oven

- Aqueous and solvent solutions

- Chamber blade system volume – 6 and 12 liter options

- Multiple cylinders available with wet thickness from 1 to 20 microns

- Plastic, paper, and metal webs at thickness of 5 microns and up

- Web widths up to 17"

- Web speeds of 50 to 5000 fpm

- In-line CDT prior to coating

- 60’ Drying/curing oven at temperatures up to 450° F

- Nitrogen purge, 600 W/in UV lamp with D/H/H+ bulb options

- Additional configuration options include:

- Wet and dry lamination

- In-line roller nip at exit of drying oven

- Aqueous and solvent solutions

- Pan volumes of 1, 2, and 12 liters

- Multiple cylinders available with wet thickness from 1 to 20 microns

- Plastic, paper, and metal webs at thickness of 5 microns and up

- Web widths up to 17"

- Web speeds of 50 to 5000 fpm

- In-line CDT prior to coating

- 60’ Drying/curing oven at temperatures up to 450° F

- Nitrogen purge, 600 W/in UV lamp with D/H/H+ bulb options

- Additional configuration options include:

- Wet and dry lamination

- In-line roller nip at exit of drying oven

- Aqueous and solvent solutions

- Chamber blade system volume – 6 and 12 liter options

- Multiple cylinders available with wet thickness from 1 to 20 microns

- Plastic, paper, and metal webs at thickness of 5 microns and up

- Web widths up to 17"

- Web speeds of 50 to 5000 fpm

- In-line CDT prior to coating

- 60’ Drying/curing oven at temperatures up to 450° F

- Nitrogen purge, 600 W/in UV lamp with D/H/H+ bulb options

- Additional configuration options include:

- Wet and dry lamination

- In-line roller nip at exit of drying oven

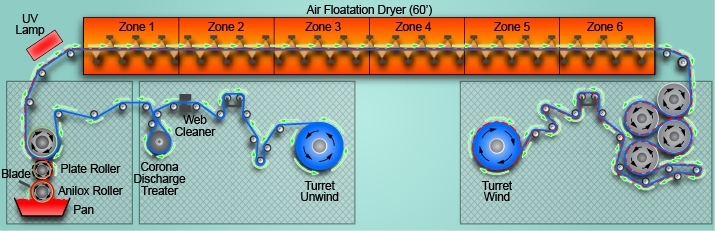

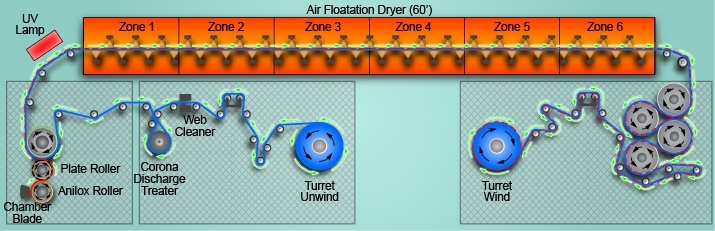

- Aqueous and solvent ink solutions

- Ink volumes of 1, 2, and 12 liters

- Plate sizes up to 16” width and 31.4” long

- Multiple anilox roller volumes and designs

- Plastic, paper, and metal webs at thickness of 5 microns and up

- Web widths up to 17"

- Web speeds of 50 to 5000 fpm

- In-line CDT prior to printing

- 60’ Drying/curing oven at temperatures up to 450° F

- Nitrogen purge, 600 W/in UV lamp with D/H/H+ bulb options

- Additional configuration options include:

- Wet and dry lamination

- In-line roller nip at exit of drying oven

- Aqueous and solvent ink solutions

- Ink volumes of 6 and 12 liters

- Plate sizes up to 16” width and 31.4” long

- Multiple anilox roller volumes and designs

- Plastic, paper, and metal webs at thickness of 5 microns and up

- Web widths up to 17"

- Web speeds of 50 to 5000 fpm

- In-line CDT prior to coating

- 60’ Drying/curing oven at temperatures up to 450° F

- Nitrogen purge, 600 W/in UV lamp with D/H/H+ bulb options

- Additional configuration options include:

- Wet and dry lamination

- In-line roller nip at exit of drying oven

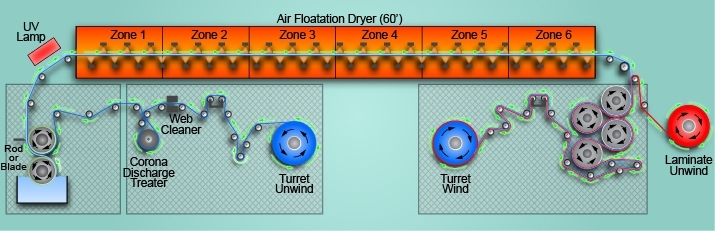

- Aqueous solutions with 30 L system volume

- Solution replenishment and recirculation options

- Multiple blade and rod options

- Plastic, paper, and metal webs at thickness of 5 microns and up

- Web widths up to 17"

- Web speeds from 100 to 5000 fpm

- In-line CDT prior to coating

- 60’ Drying/curing oven at temperatures up to 450° F

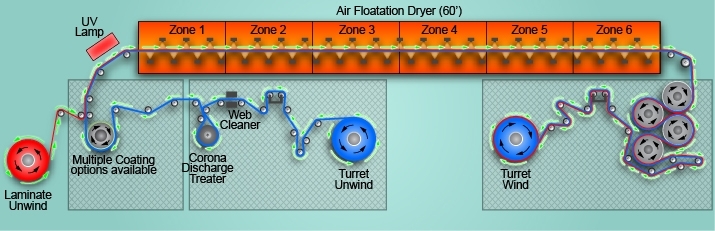

- Use any available coating option

- Plastic, paper, and metal webs at thickness of 5 microns and up

- Web widths up to 17"

- Web speeds from 10 to 1000 fpm

- Metal and rubber laminator nip rollers

- Variable laminator nip pressures

- Post nip treatment with pressure, heat (up to 220C), or UV

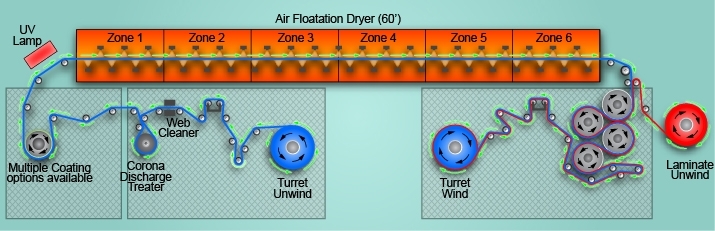

- Use any available coating option

- Plastic, paper, and metal webs at thickness of 5 microns and up

- Web widths up to 17"

- Web speeds from 10 to 1000 fpm

- Metal and rubber laminator nip rollers

- Variable laminator nip pressures

- Post nip treatment with pressure or heat (10-90 C)