KODAK Specialty Chemicals

Expertise in Custom Chemical Manufacturing and Tolling. US based.

KODAK Specialty Chemicals is a U.S.-based facility with decades of experience in custom synthesis with high-quality production. Our facilities serve diverse markets and have a long, trusted history of providing scale to innovation, particularly with heterocycles and specialty polymers.

Scale-upproduction

Scale-upproductionOur scale ranges from process development to full-scale commercial manufacturing

500+chemicals

500+chemicalsWe manufacture more than 500 different final chemicals annually

100Kmolecules

100KmoleculesWe have propriety databases of over 100,000 molecules

30Kpatents

30KpatentsWe have registered more than 30,000 patents

Capabilities

- US-based process development to full scale commercial manufacturing

- 250+ scientists, technical and production specialists

- Statistical tools for process development and control

- Production from kg scale to 250 MT/year output

- ISO 9001:2015 and ISO 14001:2015 certification

Equipment

KODAK Specialty Chemicals has a broad array of equipment available for your services.

Reactors

- 88 G/L and SS Reactors

- Distributed controls

- 100 to 3800 L

- Small Scale Production Lab 1 to 72 L

Drying

- Tray

- Double-cone rotary

Collection, Grinding and Blending

- Centrifuge

- Filter Press

- Membrane Press

- 500 kg grinder/blender with Liquid N2 capability

- 6000 kg grinder/blender with Liquid N2 capability

Special Capabilities

- Filter Dryer

- Hi-vac distillation

- Autoclaves 1 to 100 L

- Wiped film evaporator

- Ultrafiltration

Analytical Instrumentation

KODAK Specialty Chemicals' extensive analytical instrumentation capabilities give us a competitive advantage in exceeding quality specifications for custom and toll chemical manufacturing, ranging from process development to full scale commercial manufacturing.

- Atomic absorption spectroscopy

- Conductivity

- Density

- Differential scanning colorimetry

- Emission spectroscopy

- FT Infrared spectroscopy

- Gas chromatography

- Gravimetry

- High pressure liquid chromatography (HPLC)

- Inductively coupled plasma-emission spectroscopy

- Ion chromatography

- GC mass spectroscopy

- LC mass spectroscopy

- Mass spectroscopy

- Microscopy

- NMR spectroscopy

- Particle size characterization

- Potentiometry

- Refractive index

- Size exclusion chromatography

- Surface tension analysis

- Thermogravimetry

- Turbidimetry

- Ultraviolet, visible and NIR spectroscopy

- Viscosity

- X-ray fluorescence spectroscopy

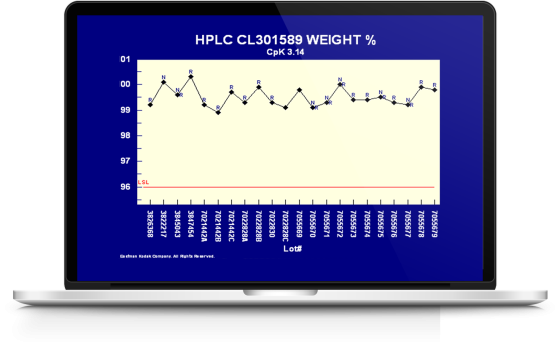

On-Site Analytics

KODAK Specialty Chemicals' world class Statistical Process System features a secure online portal enabling customers to access and monitor each step of the process in real time from their own desktops.

The group embraces a rigorous quality system that has supplied products to FDA regulated businesses as well as consumer and electronics markets – all of which have their own unique, separate and sophisticated sets of requirements. The team uses web-based analytics dashboards and lean methodologies to optimize supply chain efficiency.

Operational Excellence

From pilot scale-up of custom organic molecules to Contract Manufacturing of several metric tons, KODAK Specialty Chemicals has a long and trusted history of providing quality scale to innovation.

- Change management

- Statistical process control tools

- Design for manufacturing

- ISO 9001-2015 certification

Real-Time Quality Control

Kodak has a long history of utilizing statistical tools for process design and operation. Process verification software enables real-time tracking of key quality parameters including generating control/trend charts and process capability indices. Customers can log in remotely to monitor their processes using the same tools as Kodak’s technical staff. Few companies offer this level of transparency.

Markets Served

Kodak Specialty Chemicals has addressed the custom manufacturing and tolling needs of clients worldwide of all sizes from a wide variety of industries and applications over many decades.

- Contract Manufacturing (CMO)

- Pharmaceutical

- Industrial Specialties

- Personal Care

- Electronics

- Imaging

- Emerging energy technologies

- Green technologies

Don't see your market on the list? Contact Us.

Contact Us

Contact us to get in touch with a Kodak sales representative.