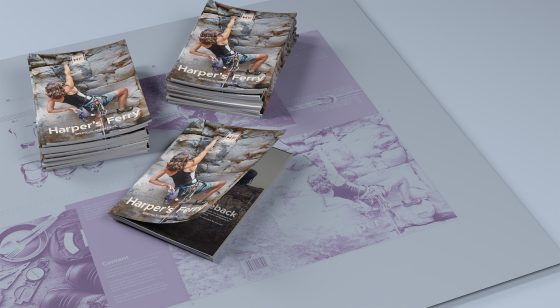

KODAK SONORA XTRA Process Free Plates

Have a fast, demanding offset operation? You need the industry's toughest, highest-contrast process free plate so you can get to press quicker. KODAK SONORA XTRA Plates are the market leader with good reason, delivering extra advantages beyond standard process free plates: enhanced image contrast for even better readability by your people and your automated equipment, and greater durability to keep presses running longer. Plus, all the time and resource savings of going process free.

- 3xstronger

Improved image contrast and clarity over Kodak's earlier generations of process free plates

- 400k / 250k

Impressions possible on web-fed presses and sheet-fed presses, plus up to 100k impressions for UV ink applications

- 6,000+

Print businesses worldwide who have unlocked the benefits of upgrading to the world's most popular process free plates

- $0spent

On the resources needed for traditional processed plates, like chemicals, water, and electricity

All the Benefits of Going Process Free

SONORA XTRA Plates deliver ultra-high performance along with all the standard perks of going process free. Eliminate plate processing, and you eliminate the extra equipment, chemicals, water, and energy it requires—not to mention the extra labor. You'll spend and waste less, meet environmental regulations more easily, and demonstrate to eco-conscious customers your shared commitment to sustainability.

Read our SONORA Plates Sustainability Datasheet (PDF)

Easy Integration and Faster Imaging

SONORA XTRA Plates work with any CTP system, for easy workflow integration that lets you get more out of your existing equipment. But they're designed to keep up with the fastest platesetters, like the KODAK MAGNUS Q800 Platesetter, at up to 84 plates per hour—so if you upgrade your CTP, you can increase your imaging productivity and get jobs to press even faster.

Exceptional Clarity and Durability

Think process-free means compromising on image clarity? Think again. As the highest-contrast process-free plates on the market, SONORA XTRA Plates let you see the smallest details and offer greater readability by automated equipment. Plus, their extra-tough substrate and coating means they hold up in just about any print environment with minimal scratches and scuffs, translating to less downtime.

No Compromises on Run Lengths

Need a robust, high-image-quality plate that delivers extra-long press runs? SONORA XTRA Plates keep up with the demands of most printers currently using unbaked processed plates: up to 400,000 impressions on web-fed presses, 250,000 on sheet-fed presses, and 100,000 for UV ink applications.

Plates that Pay for Themselves

SONORA XTRA Plates cut costs across the entire print workflow. Prepress savings are clear: no more processing equipment and resources to pay for. Even bigger savings come in the pressroom: eliminating the variability and potential defects of processing reduces plate remakes, shortens make-ready times, and improves print consistency—saving time, paper, and money.

Join the Process Free Revolution

Thousands of Kodak customers at diverse print operations worldwide have upgraded to KODAK SONORA Process Free Plates and seen cost, resource, and time savings, along with environmental perks. Explore their stories and discover how you too could benefit from switching to process free plates.

Contact Sales

Questions about Kodak print products? Interested in discussing a solution for your print business? Fill out the form below and a representative from our sales team will get back to you, usually within 24 business hours.