KODAK SQUARESPOT Imaging Technology

The perfect imaging system for an imperfect world

KODAK SQUARESPOT Imaging Technology is Kodak’s award-winning thermal imaging technology, available only in KODAK Platesetters. SQUARESPOT Technology allows printers to image plates with the highest level of accuracy, stability, and reliability, while automatically compensating for real-world problems like temperature variation, failing lasers and aging chemistry.

Episode 1: It’s Getting Hot in Here

A commercial printer in the height of summer. At 6:30 a.m., a prepress operator arrives and begins making plates for a four-color brochure for a local furniture store. Suddenly the plant’s air conditioning system acts up. The temperature at the plant starts rising. Halfway through the print run, a plate gets damaged. At 11 a.m., the pressroom requests a replacement. But the prepress room is now 5°C hotter than when the original plates were made.

What happens next?

Without SQUARESPOT: The operator makes a new plate and it’s sent to the pressroom. But because the aluminum has expanded in the heat, the image on the plate is the wrong size and the plate can’t be used. Another complete set of plates has to be made, wasting precious time and materials both in prepress and on press.

With SQUARESPOT: The prepress operator makes the new plate, which matches the damaged plate exactly, despite the heat. The run continues with no issues. He pours himself a refreshing drink.

How it works

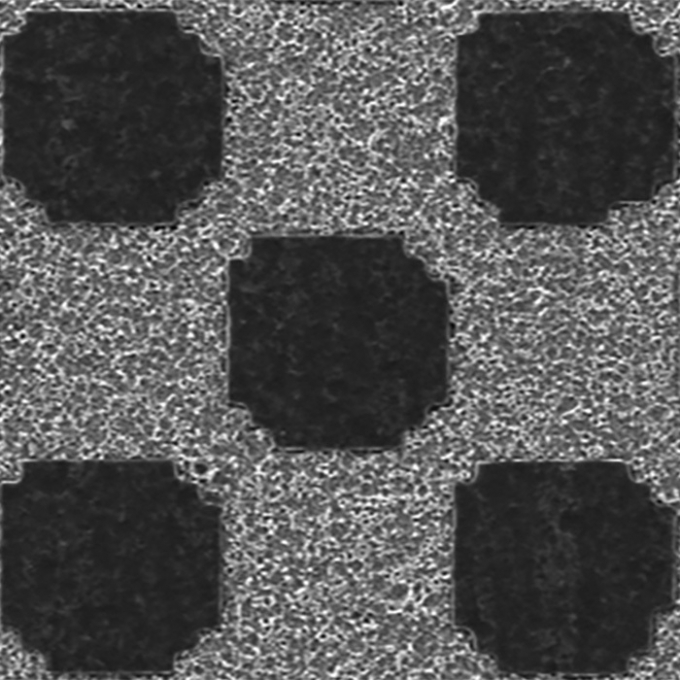

Aluminum, like many materials, expands and shrinks with changes in temperature. So plates, especially remakes, made at different times under typical shop conditions can end up being imaged at different sizes, which leads to subsequent on-press registration and color shift problems. A 5°C change in plate temperature can cause dots to shift by ½ rosette. Automatic Temperature Compensation, a feature of SQUARESPOT Imaging Technology, enables accurate registration even with variations in ambient temperature. Two sensors in the engine measure the temperature, and firmware in the imaging engine makes adjustments and places the pixel in an adjusted location to compensate for the aluminum expansion of the plate. Repeatability on one KODAK Platesetter is 0.00508 mm for the entire environmental operating temperature range of the machine. The accuracy between plates made on different machines is within 0.02032 mm.

10,000 dpi for commercial printing, 5,000 dpi for newspaper printing

KODAK SQUARESPOT Imaging Technology is Kodak’s award-winning thermal imaging technology, available only in KODAK Platesetters. SQUARESPOT Technology allows printers to reach a higher level of stability, accuracy, and reliability in their printing operation.

SQUARESPOT Technology minimizes the impact of fluctuations during the developer life-cycle and keeps dot area within manufacturing tolerances of +/-2%.

Accurate and stable imaging

Stability leads to consistency in prepress, which in turn leads to efficiency and cost savings. SQUARESPOT Technology adds stability by producing precise and robust halftone dots that are less susceptible to variations in plate, processor, and environmental conditions than other thermal or violet imaging technologies.

KODAK SQUARESPOT Advantage

Request our white paper about the advantages of KODAK SQUARESPOT Technology