Be Like Mike: Optimize Your KODAK Digital Press Performance

Mike Granata of Checkmate Graphics knows a thing or two about how to get the most out of his KODAK NEXPRESS Press. He typically runs about 100 jobs per day – most of them heavy coverage – using a variety of substrates and Fifth Imaging Unit solutions. (That adds up to roughly 500,000 impressions per month.) In fact, Mike has been keeping his press running at peak productivity almost constantly for the last 15 years.

How does he do it? By paying attention to the details with a series of Best Practices that are quick and easy to employ. Here’s a list of the Top 10 Best Practices that can help you be like Mike and optimize press performance:

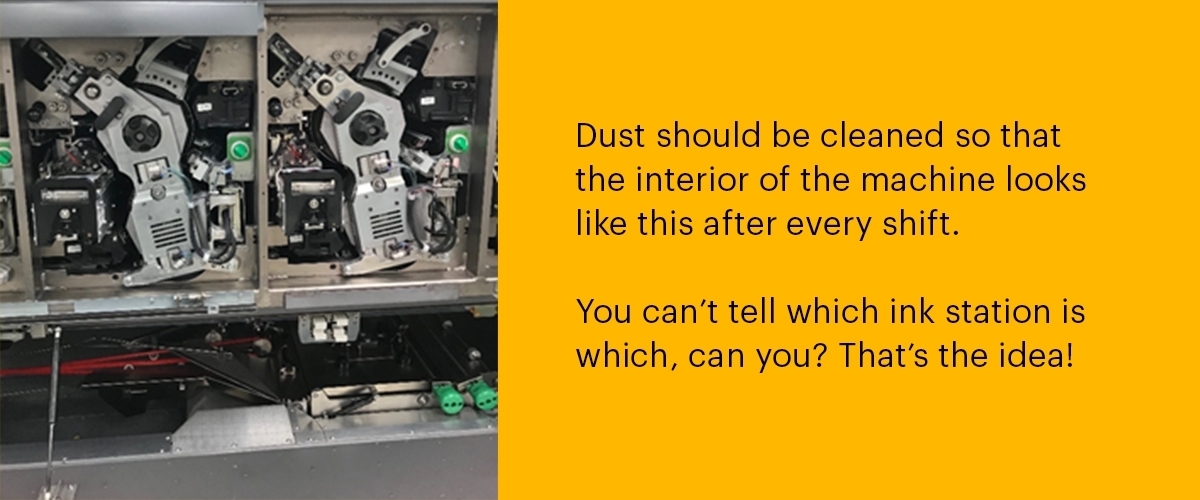

Is the press being cleaned on every shift?

Develop a process with a checklist, and keep it handy for your operators.

Are you using Light Black HD Dry Ink?

Using Light Black as a standard default in the Fifth Imaging Unit can elevate quality and improve uptime. Consider making it part of your everyday workflow.

How’s the overall cleanliness of your work area

Exterior cabinetry should be in good condition and free of dust. If you lift the door up and stand back 12 feet, the interior of the machine should be so clean that it’s impossible to tell which ink station is which.

Have you checked your fuser?

Oil color in the reservoir should be light gray. A dark gray appearance indicates excessive contamination, which could be related to the fuser temperature or a result of excessive dry ink on the fuser cleaning web. If you ever have to clean or dump the oil reservoir, you have a contamination issue. (Mike has never had to do this.)

Check your donor roller to make sure it is not dark in color or has dry ink on it. If so, it’s not being properly cleaned during shift maintenance.

Check your metering roller to make sure there is no dry ink present. If so, there may not be enough fuser oil in the sump.

Finally, are you polishing the fuser rollers? You should be. It really helps extend component life.

-

How often are you running the ICS?

If the answer is more than 2 times per shift, it may be masking a problem. Ideally, you should run the ICS once a day.

-

Do a white glove test.

Run your hand along the paper path in front of the machine. If you pick up dust, there is room for improvement.

-

Are your densitometers clean?

If so, it takes less than a minute to keep them that way.

-

How are you managing your job mix?

Splitting up coated and uncoated jobs is a great idea. If you have big coated jobs, you can even consider breaking them up with uncoated jobs. Cleaner sheets (118 gsm glossy paper) should be used after changing the web, and after medium-to-long runs of uncoated paper.

-

How is your work space organized?

Is compressed air available on both sides of the press?

Is a 3-week supply of ORC’s within 10 feet of the press?

Is your paper supply near the press?

Do you have separate work tables for fuser and non-fuser components, to minimize contamination?

Are tools and vacuum at the ready?

Are 5th stations in cases, ready to go?

Are swap sets ready to go? (Consider using them, if you don’t already.)

Have you checked your water supply lately?

If there is evidence of calcium flakes in the press, you need to change the ECS filter more often, ideally when a 2-inch water gap is visible. It pays to be proactive, so take a walk around to the back of the press and have a look.

We challenge you to follow these Best Practices for 60 days and see what happens to productivity and quality. We think you’ll be happily surprised at the difference!