More Automation, Less Space: CTP Technology Trend #1

Are you keeping up with the latest trends in prepress? Is your CTP equipment up to date?

The biggest CTP technology trends are transforming prepress by cutting costs and boosting profitability. Here’s what’s happening and how Kodak can help you keep up and get ahead:

TREND #1: More Automation, Less Space

Automation for CTP devices isn’t new, but the technology is getting more sophisticated and more compact. CTP automation takes platemaking to a new level of efficiency and productivity, reducing the chance for errors from manual plate handling and speeding up production. The more plates that can be automatically loaded, imaged, and unloaded, the more jobs you can handle in a day, increasing revenue potential and reducing costs per job.

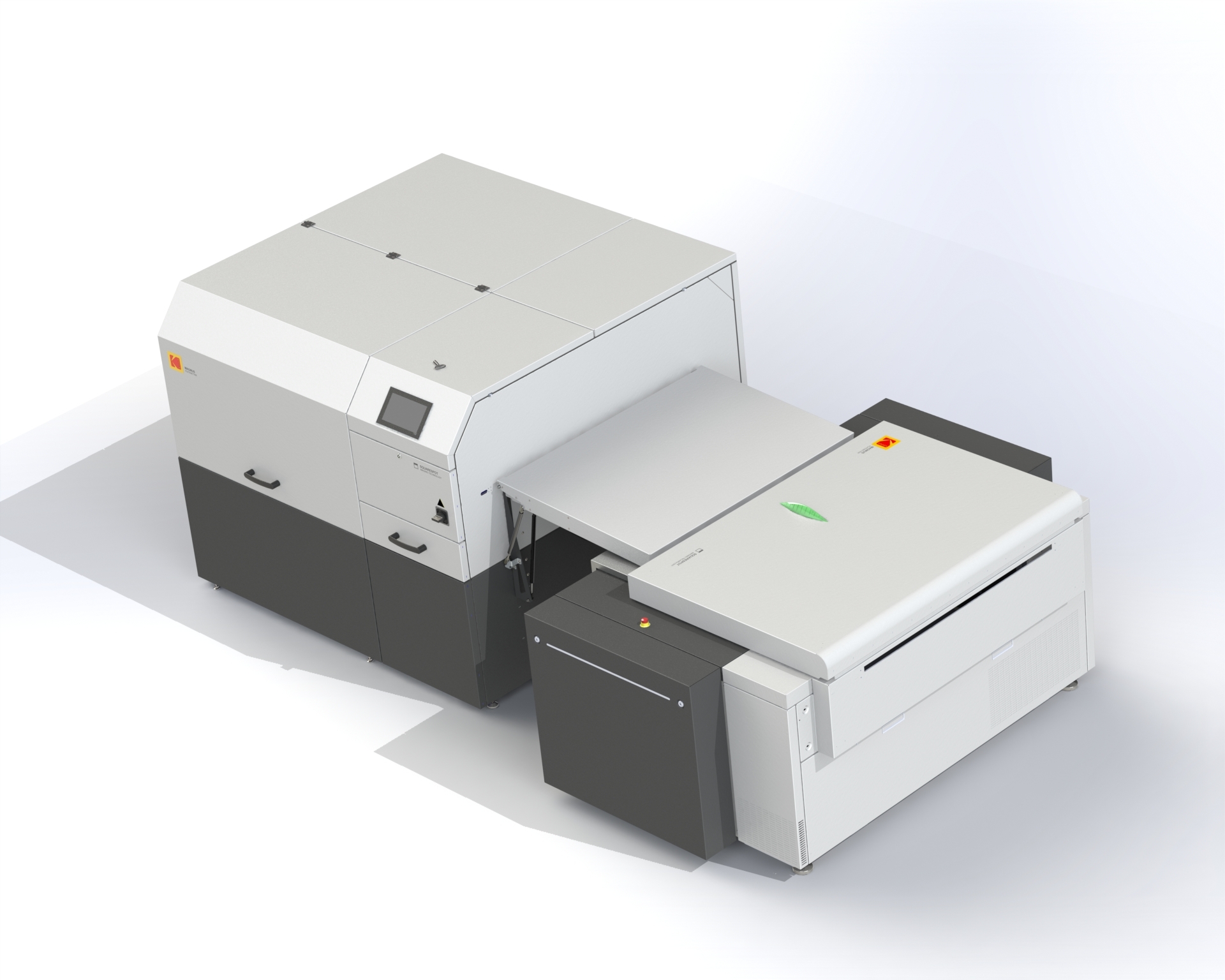

New from Kodak is the Multi-Pallet Loader (MPL) for the MAGNUS Q800 Platesetter, which has a capacity of up to 2,600 plates in four different formats – and the whole system takes up very little space.

The MPL can hold up to 2 pallets of 1,200 plates each and up to 2 cassettes with 100 plates each. Combined with the MAGNUS Q800 Platesetter’s fast imaging and the accuracy and stability of SQUARESPOT Imaging Technology, the new MPL delivers amazing productivity for printers that have no time or space to waste.

This is Trend #1 in our series of 5 CTP Technology Trends. Watch for the other trends in future blog posts.

To hear about more solutions from Kodak that can help you keep up with the latest trends, contact your Kodak representative.