Winterthur, Switzerland

PAWI Group

The industry's most advanced process-free plates help PAWI advance their business

Company

Cardboard and paper packaging primarily for the food industry, 250 employees across 3 European locations

Challenge

Continue finding new sustainable ways to simplify and streamline offset platemaking

Kodak Solution

SONORA Process Free Plates

MAGNUS Q800 Platesetter

Introduction

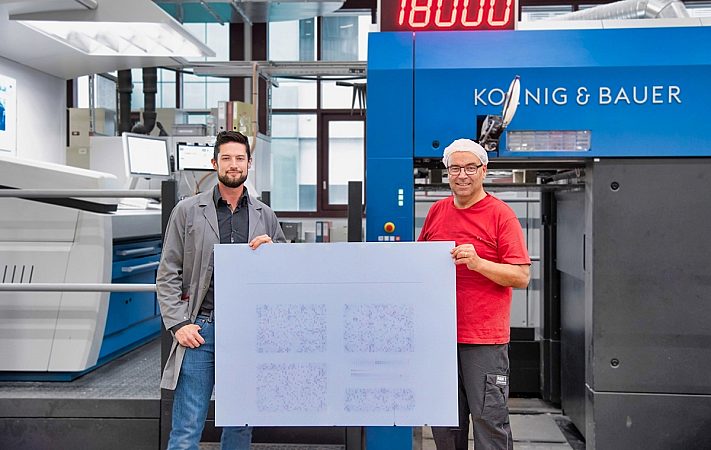

With three locations in Switzerland and Germany, PAWI Group offers end-to-end packaging solutions, from design to production, for the food industry. Sustainability has long been a company priority, and PAWI has pioneered using Kodak process-free plates for offset platemaking, which is not only greener, but also faster, simpler, and more efficient.

The Business Need

While PAWI uses multiple print technologies, the dominant mode for their high-demand cardboard carton production is offset on 3B sheetfed presses. Always looking for ways to simplify and accelerate platemaking while remaining true to an ethos of sustainability, several years ago the company moved to fully automated CTP platemaking with the KODAK MAGNUS Q800 Platesetter, and in 2017 began a transition from traditional thermal plates to the first generation of KODAK SONORA Process Free Plates. The MAGNUS Platesetter's fully automatic single cassette unit (SCU) immediately reduced labor. And by eliminating the wet chemistry processing step, the SONORA Plates also eliminated both extra equipment and the related consumption of chemicals, electricity, and water. But the company is always seeking new ways to improve quality, speed, and continuity of production, especially with their increasing use of expanded color gamut printing. This "smart printing," which adds three extra colors beyond CMYK, gives them a cost-effective alternative to spot coloring—but also means using more plates. PAWI looked to Kodak for solutions that offer other trade-offs in efficiency and savings.

The Kodak Solution

Kodak’s process-free technology aligns with PAWI's commitment to sustainability as well as production efficiency. So when Kodak introduced the next generation of these products, PAWI was eager to experience the advantages of the KODAK SONORA XTRA Process Free Plates. With a smooth transition to the new plates on the same MAGNUS Platesetter in 2021, PAWI quickly saw the benefits: enormously enhanced image contrast down to the finest detail and clean runs on press that were faster than ever. They also discovered that once imaged, the plates could be stored out of sunlight for up to five days, providing greater prepress and production flexibility when needed. PAWI uses both conventional and UV inks, and appreciated the stability of the SONORA XTRA Plates, which can achieve up to 100,000 impressions even with UV applications.

The Outcome

Aside from reducing waste and pre-press labor, PAWI's original migration to process-free technology eliminated extra equipment that gained them about 2,152 square feet (200 square meters) of on-site space to leverage for other purposes. And the payoff for their more recent transition to SONORA XTRA Plates? Shorter makereadies and faster consecutive jobs—bringing time and cost savings that more than compensate for the additional plate usage of their 7-color “smart printing” method. As a result, the company has already converted around 40% of its offset jobs to the new process, with no compromises on quality or sustainability.

Contact Us

Contact a Kodak representative to learn how our products and solutions can help grow your business.