Material Science

Interfacial Science

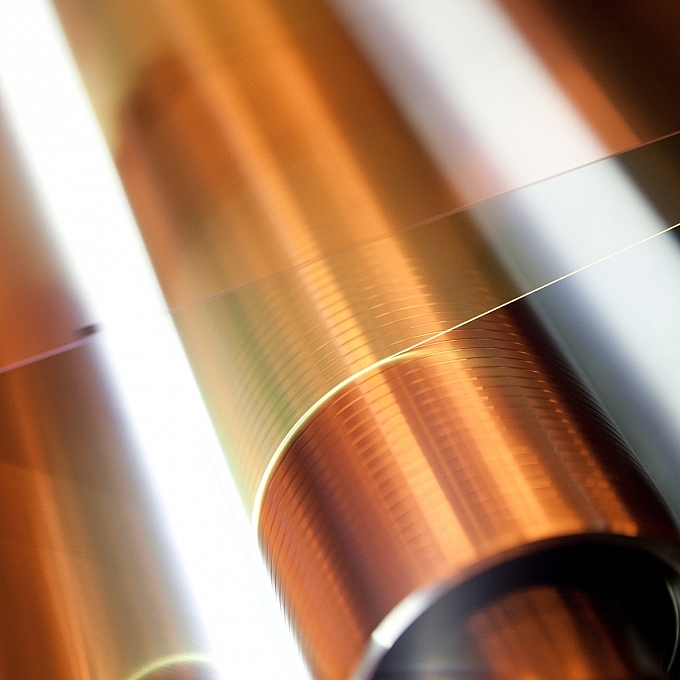

Commercial printing and the emerging functional printing applications require depositing and patterning a wide range of materials on a variety of substrates. Multiple layers are required with controlled interactions between each. Although there are similarities between these printing requirements and roll-to-roll coating on substrates, future printing applications involve many more substrates, a much wider range of materials and the need to utilize a variety of deposition techniques to produce the desired product. These factors drive the need to control a number of interfacial interactions including ink -substrate, ink -deposition device, interlayer, and print – air interfaces. The developed understanding of the chemistry and physics controlling these interactions directly translates to the invention of new materials and deposition systems to optimize system performance.

Research Topic

Formulation Stability

Of critical importance to all printing systems and applications are liquid / liquid or solid / liquid interfaces in dispersions or emulsions. Many products require the use of inks in which solid particles are dispersed within a water or solvent medium. To control particle aggregation and precipitation (or to produce a stable ink) dispersants are added to control the solid/liquid interface. New dispersants are designed to provide the stability, and may be designed to be retained in the final product as a feature or to be fleeting or easily removing. Dispersion and colloid science, chemical synthesis, analytical science and formulation chemistry are all key components of this area of focus.

Research Topic

Surface Control and Patterning

One of the more active research activities is controlling print adhesion and patterning. An aspect of this effort is wetting control, or the ability of a fluid (ink) to flow or spread on a substrate. The combination of surface energy measurement, computational fluidic modeling, materials design, and ink formulation can be used to optimize print resolution or feature size and to pattern fluid flow on a surface. Research efforts include the development of novel substrate coatings and ink additives to produce patterned hydrophobic/hydrophilic surfaces which dictate ink flow on the surface.

Research Topic

Materials’ Integrity through Printing

Polymer physics helps determine the behavior of ink leaving an inkjet printhead or ink transferring from a printing plate to media. Likewise, changing the morphology of constituent polymers can produce new nanostructured materials (after microphase separation). Each of these examples points to the complexity of the interfaces that must be managed in complex, functional materials through a printing process. Our researchers employ a variety experimental and modeling approaches to better understand the role played by all materials at interfaces. Example applications include stabilizing nanoparticle dispersions in microfluidic devices or improving adhesion between two patterned or unpatterned layers.