Why the Cloud is the answer

3D printers are very fast compared to sourcing the making of an object to a third-party but are slow if you want to make an object during a short period or with only one printer. Often 3D printers are finicky machines that have misprints. They work with very high precisions of a tenth of a millimeter and involve a combination of perfect functioning of the filaments, the software, the mechanics of the printer, the settings used in slicing the object, and even the ambient heat and humidity.

Slicing is the process where you take the digital 3D object you downloaded or made in a CAD system and specify a bunch of important parameters that are not very straightforward to understand to those without weeks or months of practice in 3D printing and that require having access to special software to complete the process. The quality of the printed object is directly proportional to how well you slice it, so here is where you notice the difference between the laypersons and the experts. Not everyone has time (or the willingness) to become experts in this esoteric discipline; most people just want the object, like from a replicator in Star Trek.

This is one of the problems with 3D printing – not all users have weeks of time to practice. You need to have at least one PC available nearby in order to install the slicing software and other support programs, and you need to be able to move the sliced object (the “gcode”) to the printer so that it can execute the instructions. Another problem is the printer needs to work for many hours to make objects, a time-consuming factor in many builds.

This is where the Cloud comes in very handy. Nowadays more printers are working with new technology to enhance functionality, and one of the newest forms of this is with a cloud management system. Basically, the 3D printer is connected via Wi-Fi or via the Ethernet port to a LAN having internet connectivity, and then it is shared to an account you create on a cloud. Having shared printers solves many problems. The shared printer can be managed remotely, using a browser and the printer’s camera, through which you can monitor the object being printed. Imagine a business that has several 3D printers using a cloud 3D printer management system. You can now do the following:

- Place them in a secure area where they can be operated 24x7 in a controlled environment (heat, electrical supply, access) by anyone, possibly very far away.

- A user can upload his/her creation to the cloud and prepare it using the optimal slicing parameters, tuned to each type of filament.

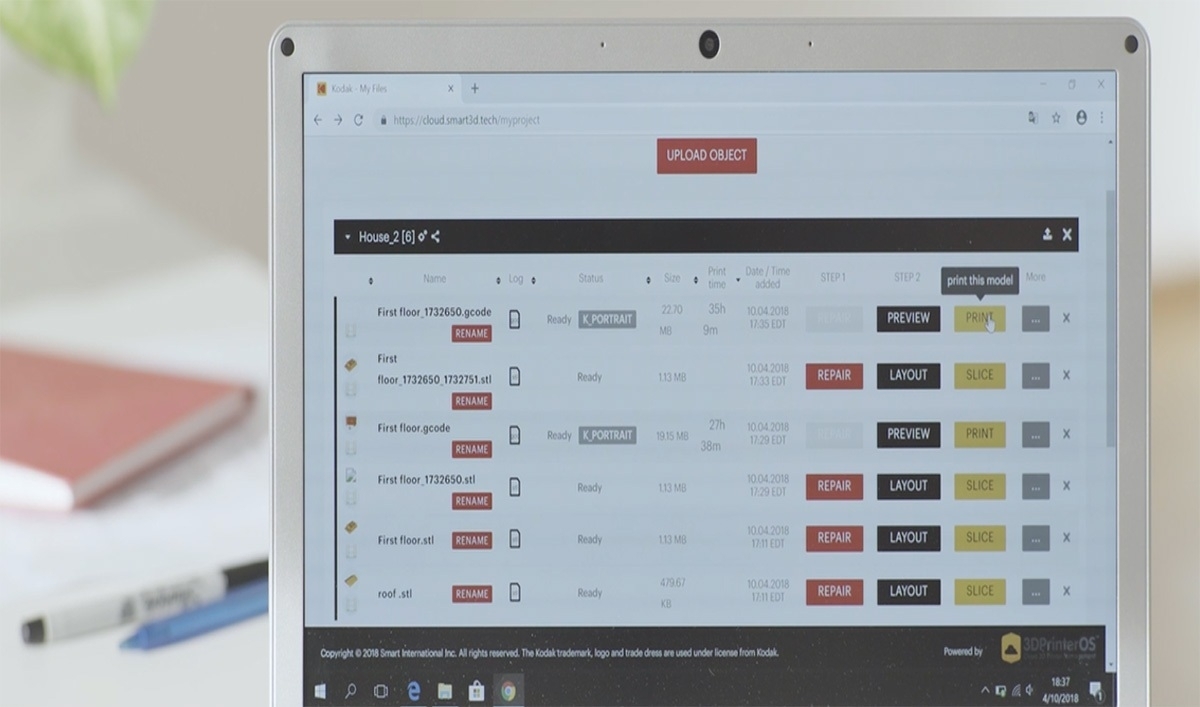

- Users can share both the source objects and the sliced objects via the cloud, organized in “folders,” ideal for working in teams or projects.

- You can repair defective objects (a common problem with STL files) using the tools in the cloud. You can arrange multiple objects or copies of your object, change their scale and orientation, and share them (with or without restrictions such as the number of prints you can make of it) with others, all without installing any software or even using a PC. You can even do it from a tablet or smartphone!

- Print objects and monitor them via the camera, while capturing a time-lapse movie of the print, which you can later keep or share with others. You don’t have to be physically close to the printer to use it. It could be in another building or another country! This way a set of printers can be shared with many users and kept under control of just one or two operators for a large number of printers, reducing operation costs.

- Queue objects so that they will be printed later. This is particularly useful for keeping them working during off-hours, so fewer printers can be used by more users.

- The Cloud will keep statistics automatically of hours printed by printer, objects printed by printer, amount of filaments used, the slicer settings used, and even the temperatures of the different components of the printer during the job. It can also keep track of what filament is loaded on what printer and how much is left on the spool, so you can send your print job to the most suitable printer.