5 ways the right flexo plate can lower your production costs

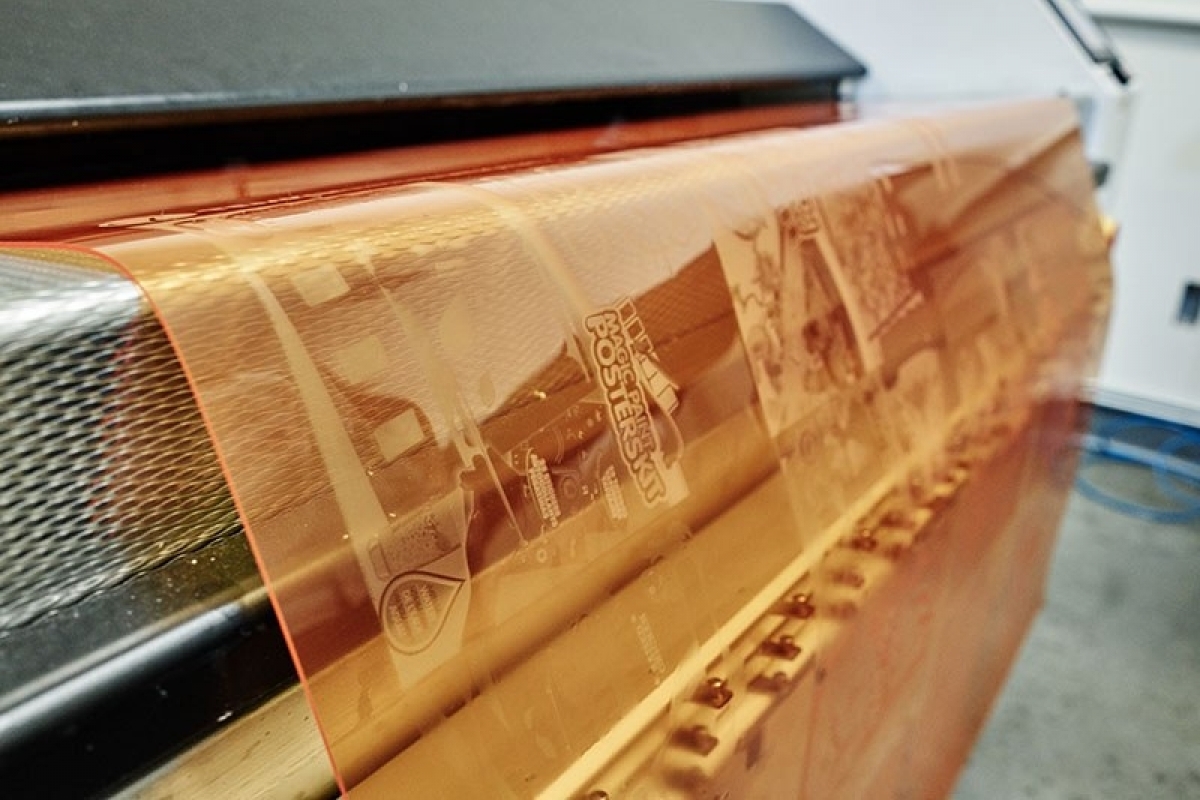

Flexo has come a long way in the last 10 years. Great quality is no longer questioned – it’s simply expected. And we all know that choice of flexo plate plays a major role in final print quality.

What seems to be less understood is the significant impact that a flexo plate has on the overall operational efficiency of a printing operation. In today’s competitive market, the right flexo plate can not only enable quality that will help you beat out your competition, but also, and most importantly, help you lower print production costs.

Here are five ways the right flexo plate can help lower YOUR print production costs:

- The right flexo plate is predictable and consistent.

If you are spending time chasing color issues and getting a match to your proof, you are wasting valuable press time. The right flexo plate can help with that. - The right flexo plate will help you reduce the number of colors per job.

Changeover times are faster with fewer colors and a more standard ink set. Whether you are trying to implement an ECG (expanded color gamut) workflow (4 color or 7 color) or simply eliminate a few Pantones. The right flexo plate gives you the dot holding, consistency, density and gamut you need to replace spot colors reliably with process builds. - The right flexo plate can help address print issues in ways you may not have considered.

Are you wasting valuable production time struggling with tape selection? Think you have an ink issue? The right flexo plate can have a tremendous impact on overall print performance. - The right flexo plate will make your presses run faster.

If your press is not running anywhere near maximum speed, you are leaving money on the table. The right flexo plate will enable you to dial up the speed WITHOUT introducing excess ink issues. - The right flexo plate can lower your spend on white ink.

How much are you spending on white ink? And how much are you having to lay down to avoid pinholes? The right flexo plate will transfer white ink more efficiently – giving you higher opacity with a lower ink film weight.

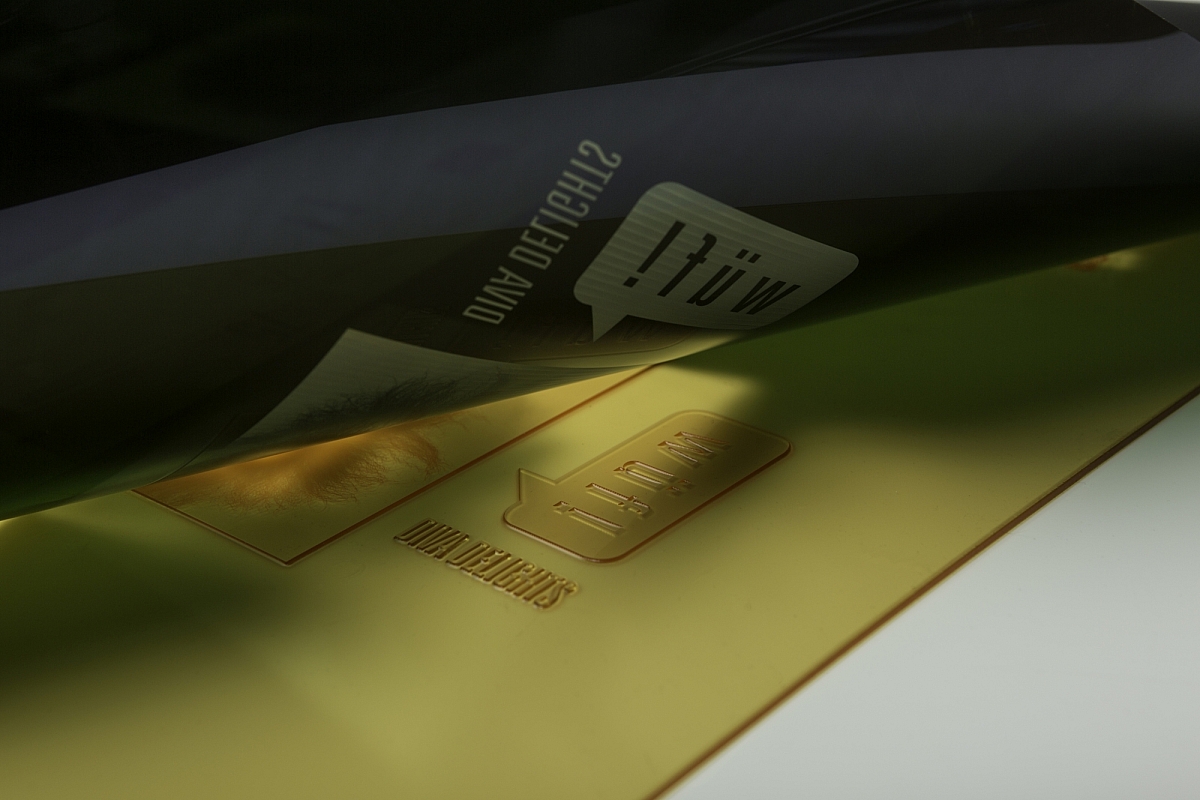

It’s no secret that sales of KODAK FLEXCEL NX Plates are growing three to four times faster than market rates. The important question is WHY? FLEXCEL NX Plates deliver the industry’s highest quality, but they also have a tremendous impact on your production costs – no matter what the job, no matter what the application. There’s a reason we’ve coined the phrase that Kodak customers ‘come for the quality’ but ‘stay for the productivity.’