就新款柯达鼎盛ULTRA 520 印刷机采访印刷部高级副总裁 Randy Vandagriff

柯达将鼎盛ULTRA 520 称作“弥补了与胶印差距的印刷机”。你们如此表述有何含义,开发该印刷机的主要目的是什么?

胶版印刷量在不断下降,但胶印仍然是质量、速度、纸张选择和长效运行的基准。但是胶印不能印刷可变的内容,并且由于印刷机运行时间越来越短,目标性越来越强,因此很难经济地进行少量印刷。

许多使用富有竞争力的 DOD 打印头的喷墨印刷机都能可变地打印事务文档以及一些简单的直邮和图书。但是它们无法与胶印质量媲美,并且不能在光面纸上印刷 - 或者如果可以,需使用非常昂贵的油墨以较慢的速度印刷。因此,它们对于许多中短期运行的应用来说太昂贵了。这就是我们所说的与胶印的差距。

为了缩小差距,我们设计并制造了革命性的新型喷墨印刷机,该印刷机以 500 fpm (152 mpm) 的速度实现胶印级的质量,可以在具有高油墨覆盖率的光面纸上以最高速度进行印刷,并实现与胶印更高的运行时长交叉,从而实现低成本生产。

鼎盛ULTRA 520 如何融入柯达现有的鼎盛喷墨印刷机产品线?

现有的鼎盛印刷机产品线基于久经考验的高速柯达连续喷墨技术。这些印刷机改变了高速商业生产向数字化转型的市场,并且日益关注每月可获得多达 2000 万张及更多 A4 图像的更高印刷量的应用。

鼎盛 ULTRA 520 印刷机采用柯达 ULTRASTREAM 喷墨技术,这是柯达第四代连续喷墨技术。对于柯达喷墨打印机产品组合的这款最新产品,我们的目标客户是每月具有约 1000 万张 A4 图像印刷量的印刷商。

鼎盛ULTRA 520 印刷机是哪种应用的理想选择?

鼎盛ULTRA 520 是多种静态和可变内容印刷应用的理想选择。该印刷机提供了两种版本:鼎盛ULTRA P520 的目标是最高具有中等油墨覆盖率的票据和账单营销印刷、出版应用和商业印刷。P520 在卷筒纸的每一侧都有两个干燥器。 鼎盛ULTRA C520 是制作直邮、插页、目录、促销手册和图书的理想选择 - 甚至适合在铜版纸上具有高油墨覆盖率的应用。这就是 C520 在卷筒纸的每一侧都有四个干燥器的原因。

数码印刷机类别是最拥挤的喷墨市场。是什么让您对柯达能在这个市场赢得胜利充满信心

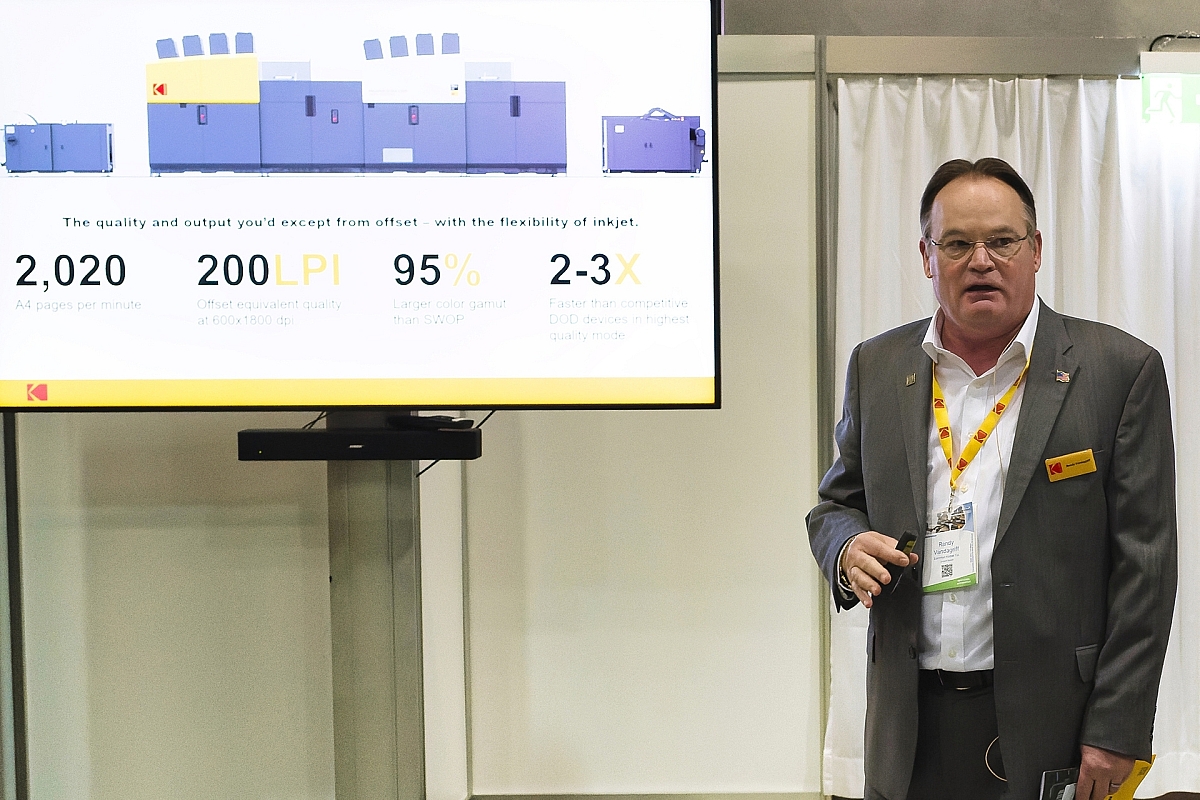

鼎盛 ULTRA 520 的独特之处在于它能够利用 ULTRASTREAM 喷墨技术提供最高的图像质量,可媲美 200 lpi 胶印,但价格实惠。此外,印刷机能够在生产速度为 500 fpm (152 mpm) 或每分钟 2,000 页 A4 纸以上,而且在光面承印物上具有高油墨覆盖率的生产环境中达到此效果。这在市场上是绝无仅有的,因此鼎盛 ULTRA 520 在竞争激烈的环境中具有出色的前景。

在 鼎盛ULTRA 520 上使用油墨可以再现的整体质量和色域与胶印相比如何?

鼎盛ULTRA 520 使用一种适合所有纸张(甚至光面纸张)的低成本 CMYK 油墨套装。柯达专有的油墨颜料研磨工艺意味着该印刷机的色域比 SWOP 胶印高 95%,并且可以匹配 93% 的 Pantone 色卡颜色(在 4 dE 之内)。这让鼎盛 ULTRA 520 能够打印具有鲜艳色彩的生动图像,可靠地呈现 CMYK 胶印色域,匹配品牌色彩并超出客户期望。

鼎盛 ULTRA 520 是柯达首款采用 ULTRASTREAM 喷墨技术的数码印刷机。ULTRASTREAM 对客户有什么特殊优势?

ULTRASTREAM 将我们的核心连续喷墨技术提升到全新的水平,通过将分辨率提高到 600 x 1800 dpi,从而提高了质量,同时减小了墨滴尺寸。结果是得到与胶印级别的图像质量,100% 数字化但以生产速度运行。柯达墨水的功能更是锦上添花。我们的水性纳米颗粒油墨为印刷机提供了超大的色域和最佳的干燥效率。

在高速生产印刷应用中,ULTRASTREAM 在哪些方面优于 DOD 等其他喷墨技术?

柯达 ULTRASTREAM 可提供极高的线条平直度、高光、细节和色彩保真度以及长期运行的一致性。墨滴的创建速度比 DOD 更快,这使得一个打印头阵列就能以 500 fpm 或 152 mpm 的速度打印 520 毫米的完整宽度,与必须减速和/或添加额外打印头的 DOD 系统完全不同。

墨滴滴到纸上的行程比 DOD 快,这样可以将墨滴准确定位,从而获得更好的质量。而且,墨滴是圆形且精确的,而 DOD 会产生畸形的墨滴和多余的卫星墨滴,导致文本和线条上出现锯齿状边缘和不太清晰的图像。与许多竞争对手的印刷机不同, 鼎盛ULTRA 520 无需在作业之间打印拆分条和色线,从而避免喷嘴堵塞。

为什么你们的喷墨解决方案依靠水性油墨?难道它们不会导致干燥更难吗,尤其是在铜版纸上油墨覆盖率很高的情况下?

柯达油墨中的保湿剂含量比竞争产品低。这意味着即使在涂料和光面纸承印物上具有较高的墨水覆盖率,干燥速度也很快。

相应地, 鼎盛ULTRA 520 具有使用近红外技术的专有智能干燥系统。这种干燥解决方案与我们的低润湿性油墨相结合,是让印刷机以最快速度在光面纸上印刷大量油墨的关键。

为什么将 鼎盛 ULTRA 520 的最大打印宽度设计为 520 毫米?毕竟,使用 ULTRASTREAM 还可以打印更宽的内容。

最大打印宽度为 520 毫米(20.5英寸),这样可实现与传统胶印机一致的多种拼版格式。这样可确保与 B2 和 B1 格式的单张纸胶印机以及印刷机已经安装的任何后处理设备无缝兼容。这种印刷宽度是 鼎盛 ULTRA 520 设计紧凑、占地面积小的原因之一,也是其投资成本极具竞争力的重要因素。

纸张是所有打印作业中最大的可变成本。鼎盛ULTRA 520 如何帮助客户控制纸张成本?

鼎盛 ULTRA 520 提供了各种功能来帮助印刷商降低纸张成本。该印刷机可以在兼容喷墨的承印物上全速印刷。选配内嵌式预涂机后,经济实惠的标准胶版纸也可用于鼎盛 Ultra 520。

由于该印刷机无需在作业之间打印拆分条和色线(这会磨损打印头),因此不会因维护打印头而浪费纸张和油墨。此外,该印刷机还采用了柯达的智能打印系统,该系统可以连续监视和优化针迹,彩色对彩色和前后套准。这也有助于避免昂贵的纸张浪费。

通常需要生产大量相对较小、分段的或 VDP 作业的高速数字印刷机,对数字前端的性能有着特殊要求。鼎盛ULTRA 520 在这方面提供了什么功能?

印刷机控制和作业管理由柯达 900 印刷管理器处理,这基于非常高效的硬件。数字前端采用最先进的 ADOBE APPE 5 RIP,能以峰值性能运行印刷机,具有易于设置、准备就绪且复杂的工作排队系统。该系统接受所有领先的文件格式,例如 PDF、PDF/VT 和 AFP,并支持与兼容 JDF/JMF 的印前和印后系统连接。此外,与柯达印能捷工作流程的优化接口最大限度提高了生产效率和数据安全性。这些功能确保了鼎盛 ULTRA 520 能最有效地融入当今的生产环境中。

How do the overall print quality and the color gamut that can be reproduced with KODACHROME Inks on PROSPER ULTRA 520 compare with offset?

PROSPER ULTRA 520 uses KODACHROME Inks - one reasonably priced CMYK ink set for all papers, even glossy. Kodak’s proprietary ink pigment milling process means the press delivers a 95% larger gamut than SWOP offset and can match 93% of Pantone colors (within 4 dE). This enables PROSPER ULTRA 520 to print vivid images with vibrant colors, reliably render the CMYK offset gamut, match brand colors and exceed customer expectations in virtually all applications, with less ink laydown.

PROSPER ULTRA 520 is Kodak’s first digital press to employ ULTRASTREAM Inkjet Technology. What advantages does ULTRASTREAM have for printers?

ULTRASTREAM takes our core continuous inkjet technology to the next level, enhancing the quality by increasing the resolution to 600 by 1,800 dpi, but also decreasing the ink drop size to just 3.75 pL (picoliter). The result is an image quality that's equivalent to offset at 200 lpi, 100% digital but running at production speeds. What adds to that is the capability of KODACHROME Inks. The water-based nanoparticulate pigment inks have the smallest and most uniform distribution with low humectant levels to offer an exceptionally large color gamut and optimum drying efficiency.

In what ways is ULTRASTREAM superior to other technologies like Drop-On-Demand (DOD) in high-speed applications?

KODAK ULTRASTREAM provides the ultimate in line straightness, highlights, detail and color fidelity as well as consistency over long runs. Ink drops are created faster than DOD inkjet and this allows just one array of print heads to print the full 520 mm width at 152 mpm or 500 fpm, unlike DOD systems that must slow down and/or add extra print heads. Drops travel to the paper faster than DOD and this targets them exactly for better quality. Moreover, drops are round and precise, unlike DOD that creates misshapen drops and extra satellite drops, leading to jagged edges on text and lines and less sharp images. And unlike a number of rival presses, PROSPER ULTRA 520 does not need to print spit bars and color lines between jobs for avoiding nozzle clogging, which reduces waste and increases efficiency.

Why do your inkjet solutions rely on water-based inks? Don’t they make drying more difficult, particularly with high ink coverage applications?

Kodak's inks have lower levels of humectants than the competition. That means faster drying, even with high ink coverage on coated and glossy papers. Correspondingly, PROSPER ULTRA 520 features a proprietary intelligent drying system using near-infrared technology. This drying solution combined with our low humectant KODACHROME Inks are the key to printing heavy ink coverage on glossy papers at top speed.

Why did you design PROSPER ULTRA 520 for a maximum print width of 520 mm? After all, larger widths would also be possible with ULTRASTREAM.

The print width of 520 mm (20.5 inches) allows for a wide variety of imposition formats consistent with traditional offset presses. That ensures seamless compatibility with sheetfed offset presses in B2 and B1 sizes as well as with post-processing equipment that printers already have installed. This print width also plays a part in PROSPER ULTRA 520’s compact design and small footprint and, not least, contributes to its competitive investment costs.

Kodak、Prosper、Prinergy 和 Ultrastream 是伊士曼柯达公司的商标。

High-speed digital presses, which are typically expected to print a large number of smaller, segmented or VDP jobs, place special demands on the digital front end’s performance. What does PROSPER ULTRA 520 offer in this respect?

Press controls and job management are handled by the KODAK 900 Print Manager, which is based on compact yet extremely powerful hardware. The digital front end employs the ADOBE APPE 5 RIP and runs the press at peak performance with easy set-up, make-ready, and a sophisticated job queuing system. It accepts all the leading file formats such as PDF, PDF/VT, and AFP and supports connectivity to JDF/JMF compatible prepress and finishing systems. Unlike rival systems that require costly options and add-ons, the KODAK 900 Print Manager comes fully configured to run the most complex variable data jobs from day one. Furthermore, an optimized interface with KODAK PRINERGY Workflow maximizes production efficiency and data security. These features ensure optimum integration of the PROSPER ULTRA 520 Press in today’s production environments.

Kodak, Kodachrome, Prosper, Prosper Ultra, Prinergy and Ultrastream are trademarks of Eastman Kodak Company.