Pilot-Scale Coating

With our service that optimizes the roll-to-roll manufacturing process, your product will be made to your exact specifications, all at a cost that will win in the marketplace. Select from a variety of process options that will enable you to coat or print your aqueous or solvent-based solutions over a wide range of thicknesses onto paper, plastic, or metal substrates.

Lab-Scale Coating Machines

Kodak offers lab-scale coating machines designed to optimize your materials and demonstrate the viability of using a roll-to-roll process to manufacture your product. These machines typically require 0.5-5.0 L of coating solution and can be easily reconfigured within an event to investigate a range of process options.

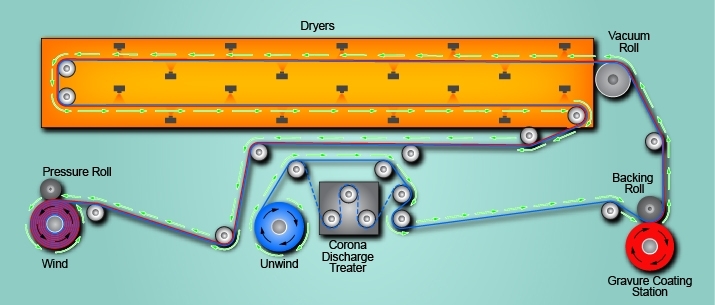

GC1 Coater

A variety of gravure cylinders are available to allow you to customize the pattern and thickness of your intended product. This coater provides gravure coating, and features:

- Aqueous and solvent solutions

- Solution volumes as low as 300 cc

- Forward direct with pan and weir feed options

- Temperature control on gravure cylinder

- Multiple gravure cylinders available to be custom patterned as required

- Nitrogen-inerted pan/cylinder option

- Plastic, paper, and metal webs at widths up to 6 in.

- Web speeds of 50 to 400 fpm

- Inline CDT prior to coating

- Drying/curing temperatures up to 225° F

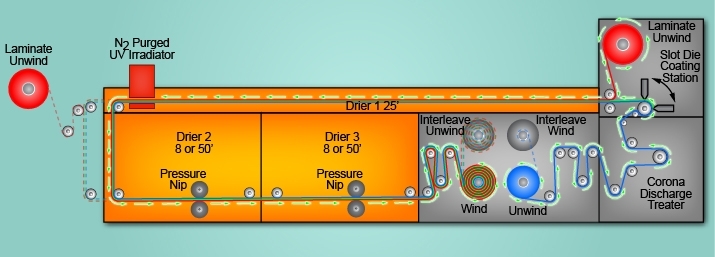

RC5 Coater

A variety of process options (including lamination and UV curing) are available to allow you to customize the process that will best meet your product needs. This coater provides slot die, and features:

- Aqueous and solvent solutions up to 10,000 cps

- Solution volumes as low as 500 cc

- Gear pump and pressure vessel delivery options

- Plastic, paper, and metal webs at widths up to 10 in.

- Web speeds of 5 to 50 fpm

- In-line CDT prior to coating

- Drying/curing temperatures up to 250° F

- Humidity control of dryer air from 20° F to 60° F dew point

- Nitrogen purge, 300 W/in UV lamp with D/H/H+ bulb options

- Additional configuration options include:

- Wet and dry lamination

- Nitrogen-inert coating

- In-line roller nip (variable locations)

Pilot-Scale Coating Machine

Kodak's DPC coater is designed to allow you to develop, optimize and prototype your final manufacturing process. This machine can be configured to support a wide variety of processes. The primary process options that are available include:

- Slot die, gravure (forward/reverse/offset), flexographic and dip coating

- Wet and dry lamination

- Thermal, IR and UV drying/curing options

Supporting Services

Kodak offers all the necessary supporting services that are required to support the use of all our coating processes. These services include:

- Material and inventory management

- Solution preparation/mixing (including hazardous materials)

- Analytical testing

- Calendaring

- Wide roll slitting (to widths required by our coating machines)

- Slitting and packaging (to your final product format)

- Engineering support

Contact Us

Contact a Kodak representative to learn how our products and solutions can help grow your business.